Description

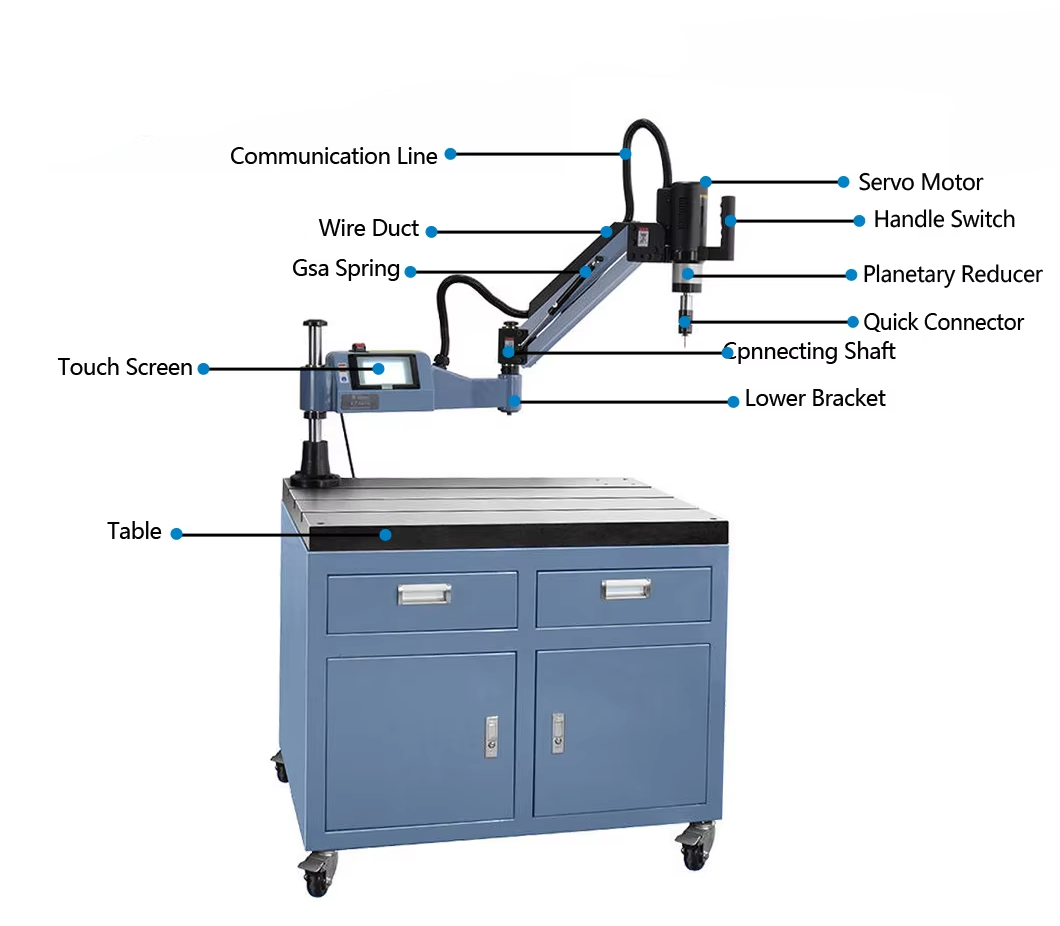

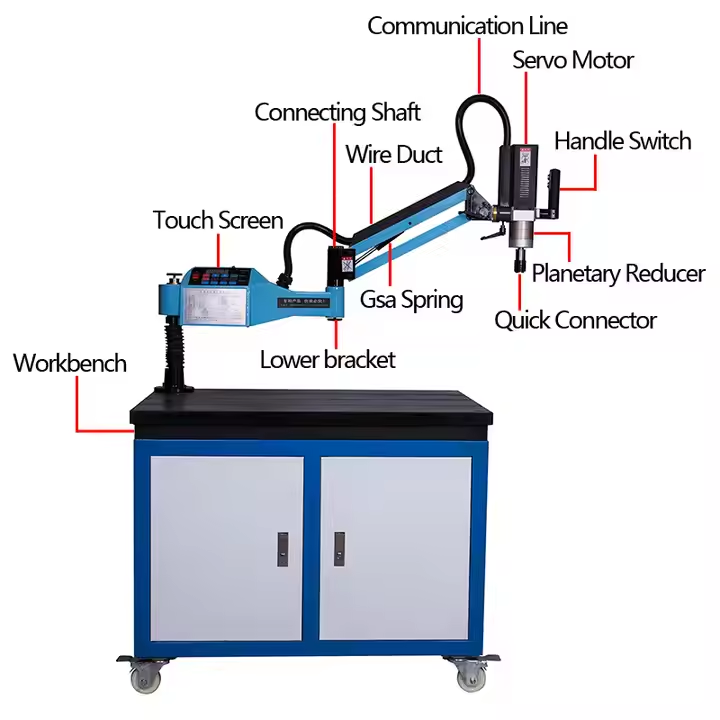

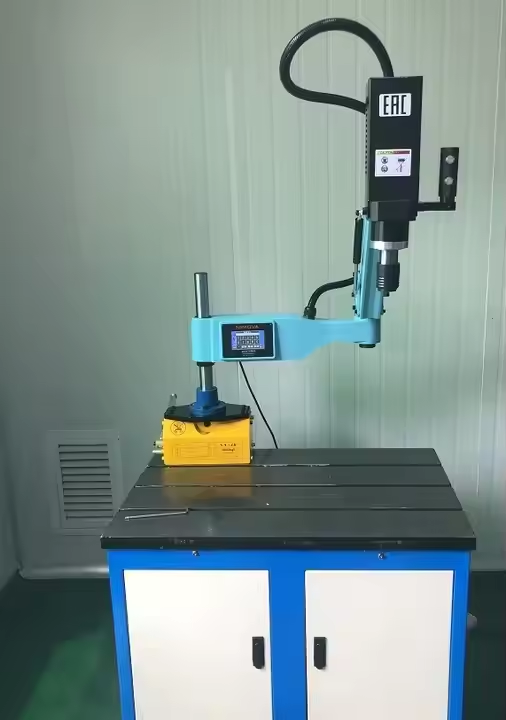

Servo Motor Electric Tapping Machine With Flexible Arm robot Arm SCJSRA Series

| Model | SCJSRAM3-M16 | SCJSRAM6-M30 | SCJSRAM6-M36 | SCJSRAM12-M48 |

| Tapping capacity | M3-M16 | M6-M30 | M6-M36 | M12-M48 |

| The motor | 600W/800W | 1200W | 1200W | 1200W |

| Speed | 0-312r/min | 00-200r/min | 0-140r/min | 0-200r/min |

| Working radius | 389-1200mm | 580-1200mm | 580-1200mm | 580-1 200mm |

| voltage | 220V | 220V | 220V | 220V |

| power | 0.8kw | 1.2kw | 1. 8kw | 2.8kw |

| Volume (mm) | 650*670*190 | 820*740*190 | 820*740*190 | 1100*1000*200 |

| Weight net weight (excluding table) | 35kg/28kg | 55kg/48kg | 55kg/48kg | 110kg/102kg |

| Table size | 90*60*80cm | 90*60*80cm | 90*60*80cm | 90*60*80cm |

Machine Features:

1, the machine adopts servo drive control, with intelligent torque protection, instead of the traditional lathe, drilling machine or manual tapping limitations.

2, Advanced mechanical design, a variety of processes using mold castings, the overall rigidity is strong, durable, non deformation, beautiful appearance.

3. The high definition touch screen is simple and flexible. It can realize the vertical and horizontal work of complex and heavy workpiece, locate quickly, and process accurately.

4, Stepless speed change, manual, automatic, linkage three modes of work, whatever you choose.

5, Automatic mode can effectively control the depth of tapping, without the operation button, automatic control by depth controller.

6, Repeated positioning fast, tapping speed, high production efficiency.

Non Standard Goods:

Non standard goods refer to goods or equipment that are not made according to the work standards and specifications published by the country, but are made according to one’s own needs and plans. And if the appearance or function is not included in the national equipment product catalog, products produced, modified or customized based on user requests and standardized products are called non-standard products.

Enquiry Notice for Customerized Machine:

1. The customer provides the required parts for processing, assembly, and riveting, and clarifies a series of information about the parts, such as tolerances, burrs, deformation, etc.

2. We will conduct a series of analyses on the components provided by the customer and provide a quotation

Reviews

There are no reviews yet.