Description

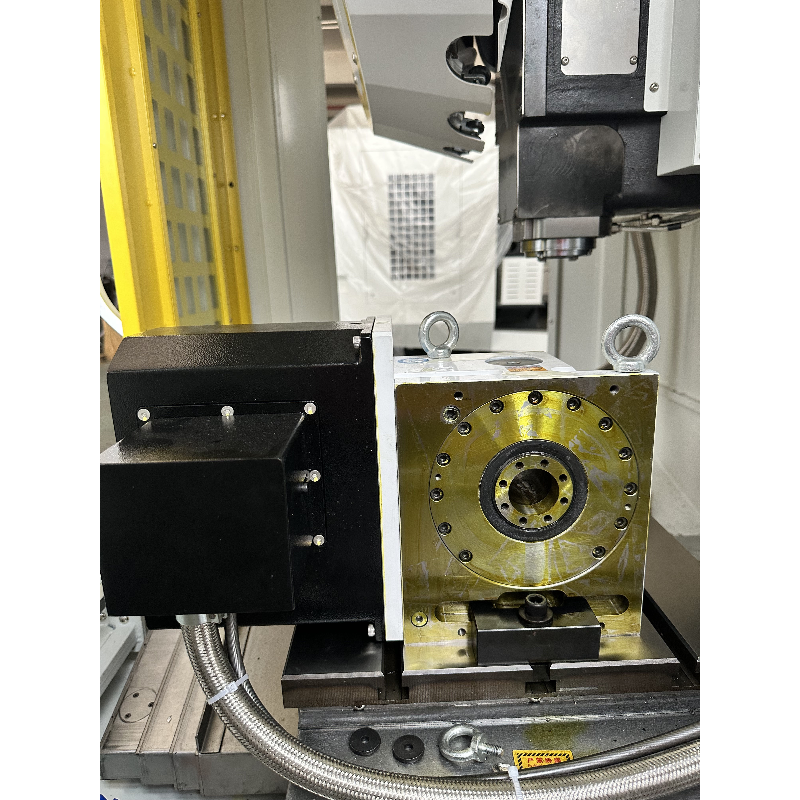

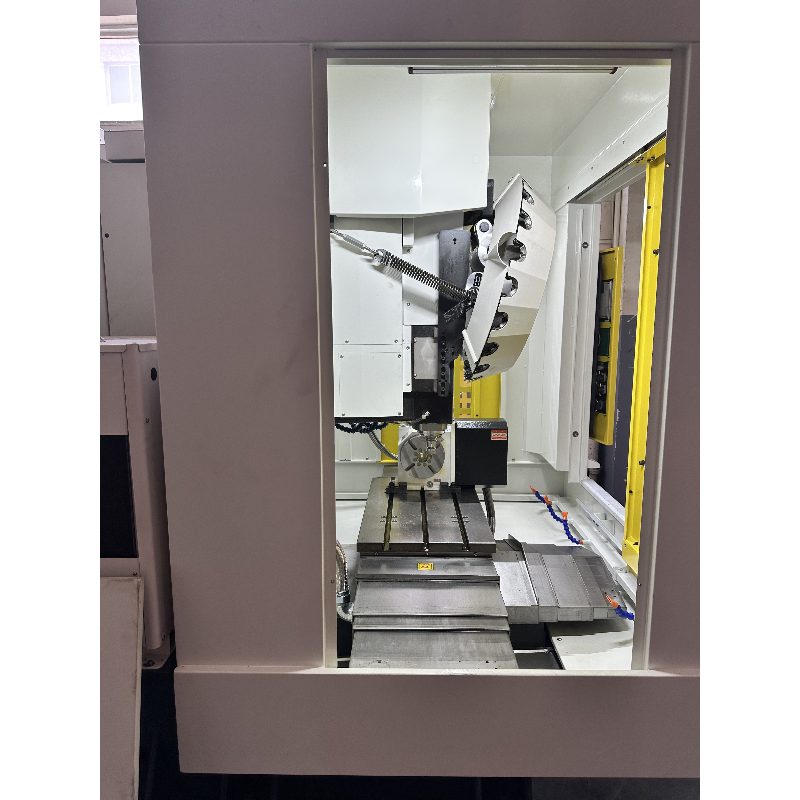

BT30 5.5KW Servo Motor Heavy Duty Drilling Tapping Center Machine SCY450-8T

Machine Features:

1.Machine tool gross also adopts resin sand precision casting, large span herringbone column, stable support,and after the second artificial aging treatment, to ensure the machine

2.The machine is compact in appearance, occupies little space, and can enter most of the freight elevators,saving the user’s resources on the ground floor of the plant.

3.The machine is equipped with standard locking tool holder, shank holder and tool box, which is very convenient for users to use.

Product Introduction:

1.Adopting clamping arm type tool magazine, sequentialtool selection, stableand reliable tool change

2.Adopting high rigidity spindle motor, mainly used for drilling and tapping of steel parts, cast iron parts and copper and aluminum parts, as well as light-load milling processing, with great versatility and excellent performance.

Advantages of Roller Guideway:

1.High precision: Roller guide can realize micron-level positioning accuracy to meet the needs of high-precision equipment.

2.Rigidity: able to withstand large loads, under the load of small deformation to ensure the stability of the equipment and precision of high-speed. Roller guide supports higher running speed, to adapt to the needs of high-speed equipment.

3.Long life: has a long service life, can realize millions of times the number of cycles, to ensure the long-term stable operation of the equipment.

|

ITEM

|

UNIT

|

SCJT450-8T

|

|

Size of working table (L*W)

|

mm

|

500*300

|

|

T-slot (number of slots*slot width*slot)

|

mm

|

3*12*100

|

|

Maximum table load

|

kg

|

200

|

|

Maximum travel(X*Y*Z)

|

mm

|

500*300*300

|

|

Distance from spindle nose to table surface

|

mm

|

120~420

|

|

Rapid traverse speed (X*Y*Z)

|

mm/min

|

30*30*30

|

|

Feed speed(X*Y*Z)

|

mm/min

|

10000

|

|

Spindle taper hole specification

|

–

|

BT30

|

|

Maximum spindle speed

|

rpm

|

6000 / 4000

|

|

Spindle drive mode

|

–

|

Belt type

|

|

Tool magazine type

|

–

|

Disc clamping arm type

|

|

Tool shank type

|

–

|

BT30

|

|

Maximum number oftools

|

PCS

|

8T

|

|

Max. tool diameter

|

mm

|

φ80

|

|

Max. tool diameter (without propper)

|

mm

|

φ120

|

|

Max. tool length

|

mm

|

150

|

|

Max. tool weight

|

kg

|

3

|

|

Tool change time (T to T)

|

sec

|

1.8

|

|

Positioning accuracy

|

mm

|

±0.01/300

|

|

Repeat positioning accuracy

|

mm

|

±0.008/300

|

|

Spindle servo motor

|

kw

|

3.7/5.5

|

|

Control System

|

–

|

GUANG TAI

|

|

Floorspace(L*W*H)

|

mm

|

1400*1500*2200

|

|

Machine Weight(Gross)

|

kg

|

1300

|

Reviews

There are no reviews yet.