Description

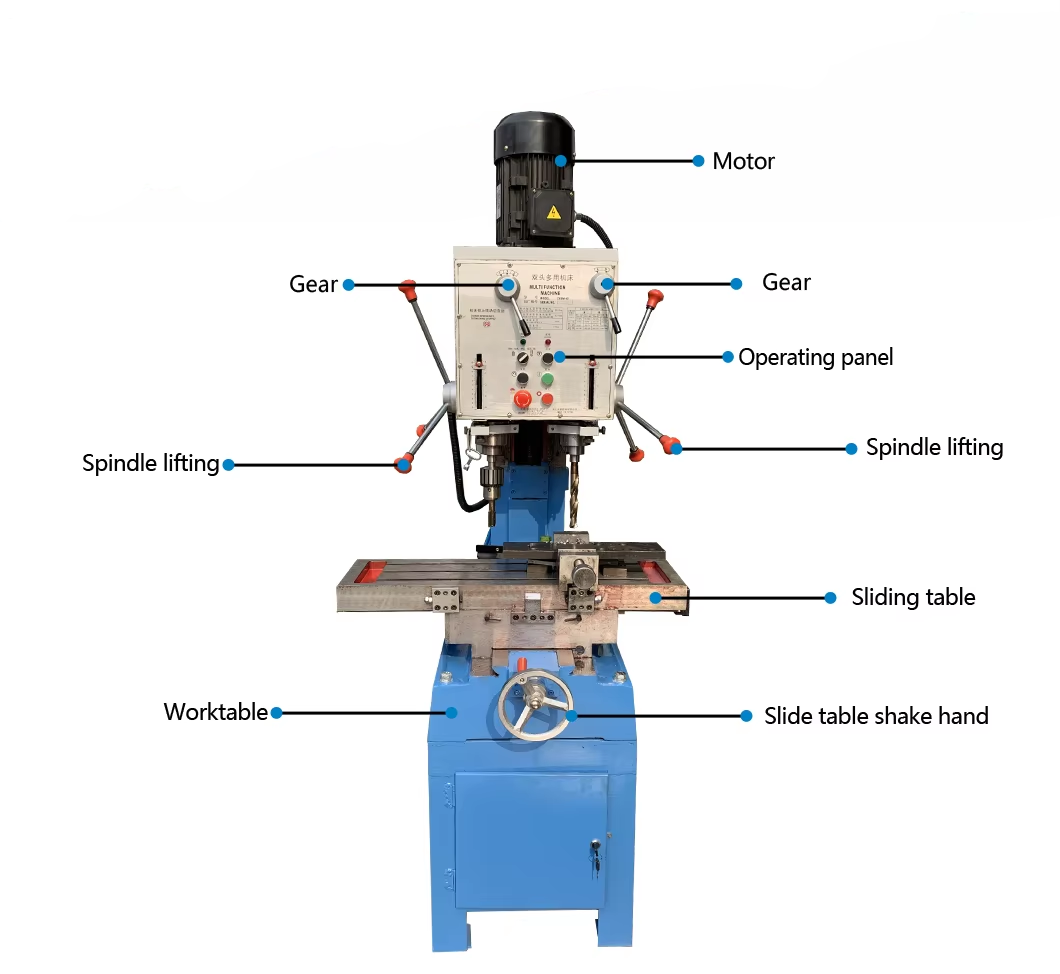

Double Spindle Compound Machine Vertical Automatic Drilling Tapping Compound Machine SCJDSM Series

| Model | SCJDSM-45 | SCJDSM-45(A) |

| Max.Drilling capacity | 31.5mm | 45.5mm |

| Max.The spindle taper | MT33 | MT36 |

| Maximum spindle stroke | 100mm | 120mm |

| Spindle taper | MT3 | MT4 |

| Main spindle to working table | 515mm | 665mm |

|

Spindle speed

|

Drill: 75;130;240;390;670;1200r/min

Tap or Ream:35;65;120;190;330;600r/min

|

|

| Table size | 800*240mm | 1000*240mm |

| Table travel | 200*200mm | 400*200mm |

| The motor | 2.2kw | 2.2kw |

| Voltage | 380V | 380V |

| Frequency | 50HZ | 50HZ |

| Weight | 550kg(G.W.)/500kg(N.W.) | 650kg(G.W.)/600kg(N.W.) |

| Volume | 1090*890*1900mm| | 1090*1090*2050mm |

Machine Features:

1. Special design of positive and reverse motor, low inertia to prevernt breakage of tapping

2. Functional action can be selected for perforated teeth,blind teeth and perforated teeth

3. The spindle rotation speed is high and the spindle speed is low when the tapping is reversed, and the accuracy of tapping depth is 0.1mm

4. It is especially suitable for the processing of fine and blind holes in precise hardware such as watches, glasses, mobile phones and cameras

5. It can be equipped with multi-axis tapping device to complete one-off multi-hole tapping and automatic tapping at the same time, which improves the production efficiency

6.Solid column, tempered to eliminate stress, hard chromium plating, friction resistance, no rust

Non Standard Goods:

Non standard goods refer to goods or equipment that are not made according to the work standards and specifications published by the country, but are made according to one’s own needs and plans. And if the appearance or function is not included in the national equipment product catalog, products produced, modified or customized based on user requests and standardized products are called non-standard products.

Enquiry Notice for Customerized Machine:

1. The customer provides the required parts for processing, assembly, and riveting, and clarifies a series of information about the parts, such as tolerances, burrs, deformation, etc.

2. We will conduct a series of analyses on the components provided by the customer and provide a quotation

Reviews

There are no reviews yet.