Description

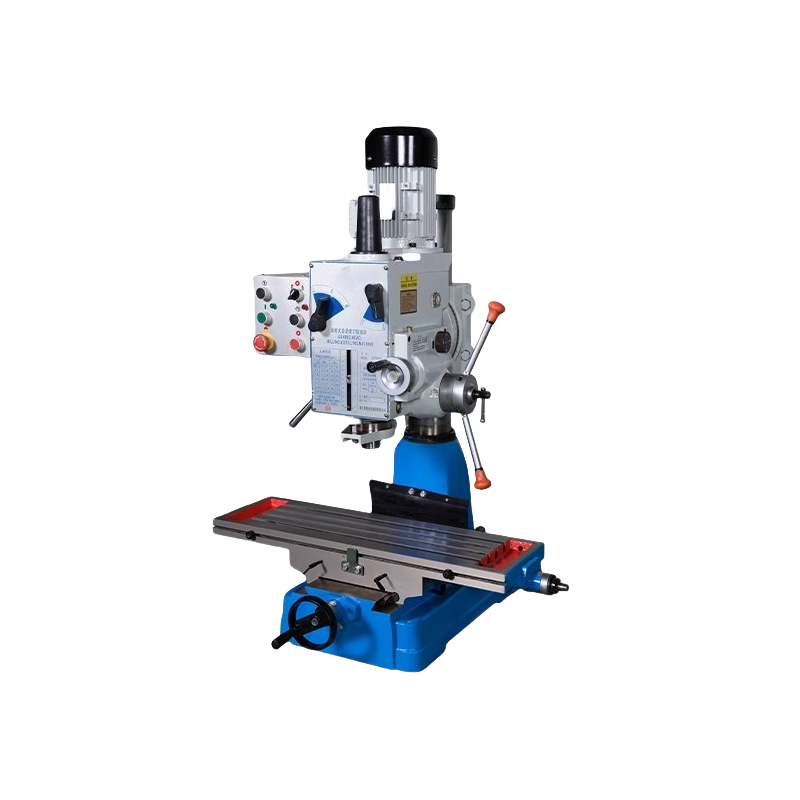

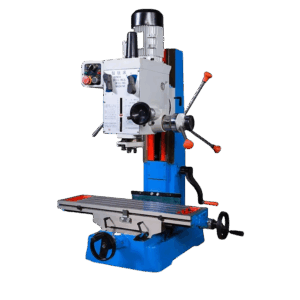

40mm Auto Feeder Pillar Milling And Drilling Machine SCJGDM40 Series

| Model | SCJGDM40r(round pillar,auto feeder) | SCJGDM40d(round pillar,auto feeder) |

| Max.Drilling Dia | Iron 40mm/Steel 32mm | Iron 40mm/Steel 32mm |

| Max.Tapping Dia | / | / |

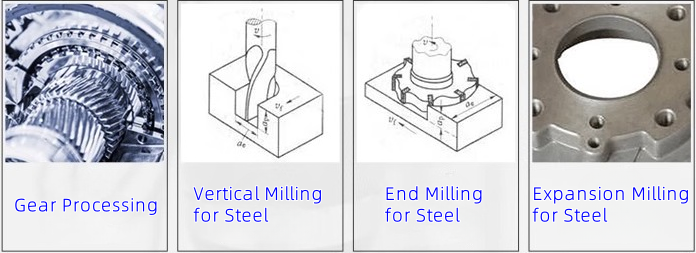

| Max vertical milling diameter | 22mm | 22mm |

| Max end milling width | 80mm | 80mm |

| Maximum spindle stroke | 110mm | 110mm |

| Column diameter | 115mm |

115mm |

| Distance from spindle center to column busbar | 261.5mm | 261.5mm |

| Max distance from spindle end to worktable | 450mm | 450mm |

| Max distance from spindle end to base | / | / |

| Spindle taper | MT4 or R8 | MT4 or R8 |

| Spindle Speed | 50-1250r/min | 50-2500r/min |

| Speed grade | 6 | 12 |

| Spindle feed rate |

0.12/0.18/0.25 | 0.12/0.18/0.25 |

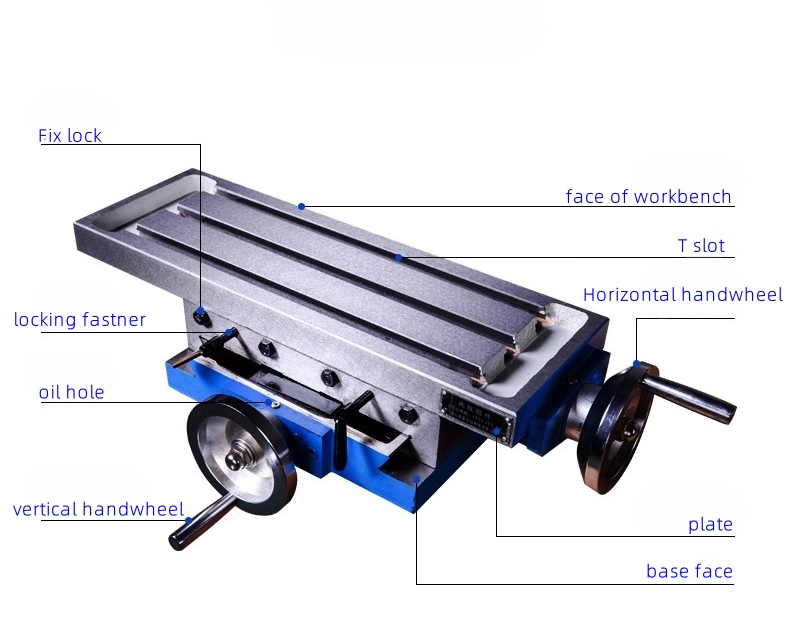

| Worktable size | 730*210mm / 820*240mm(option) | 730*210mm / 820*240mm(option) |

| Workbench stroke | 450*170mm/540*170mm(option) | 450*170mm/540*170mm(option) |

| Base size | 605*400mm | 605*400mm |

| The motor | 1100 single phase/1500w triphase | 1100 single phase/1500w triphase(two-speed motor) |

| Voltage | 380V | 380V |

| Frequency | 50HZ | 50HZ |

| Weight | 405kg(G.W.)/360kg(N.W.) | 405kg(G.W.)/360kg(N.W.) |

| Overall | 107*7700*1240mm | 107*7700*1240mm |

Machine Features:

1. High power pure copper core motor,multi speed regulation pure copper wire motor

2. Gear drive,overcoming the characteristic of belt slippage

3. The spindle box can be tilted at a positive or negative 45 ° angle, and the machine head can be tilted at a 45 ° angle for easy use

4. The precision and high-quality spindle box is made of high-quality cast iron as a whole

5. Auto Feeder,without cooling system

6. Frame,knife and XY 2Axis digital is option

Non Standard Goods:

Non standard goods refer to goods or equipment that are not made according to the work standards and specifications published by the country, but are made according to one’s own needs and plans. And if the appearance or function is not included in the national equipment product catalog, products produced, modified or customized based on user requests and standardized products are called non-standard products.

Enquiry Notice for Customerized Machine:

1. The customer provides the required parts for processing, assembly, and riveting, and clarifies a series of information about the parts, such as tolerances, burrs, deformation, etc.

2. We will conduct a series of analyses on the components provided by the customer and provide a quotation

Reviews

There are no reviews yet.