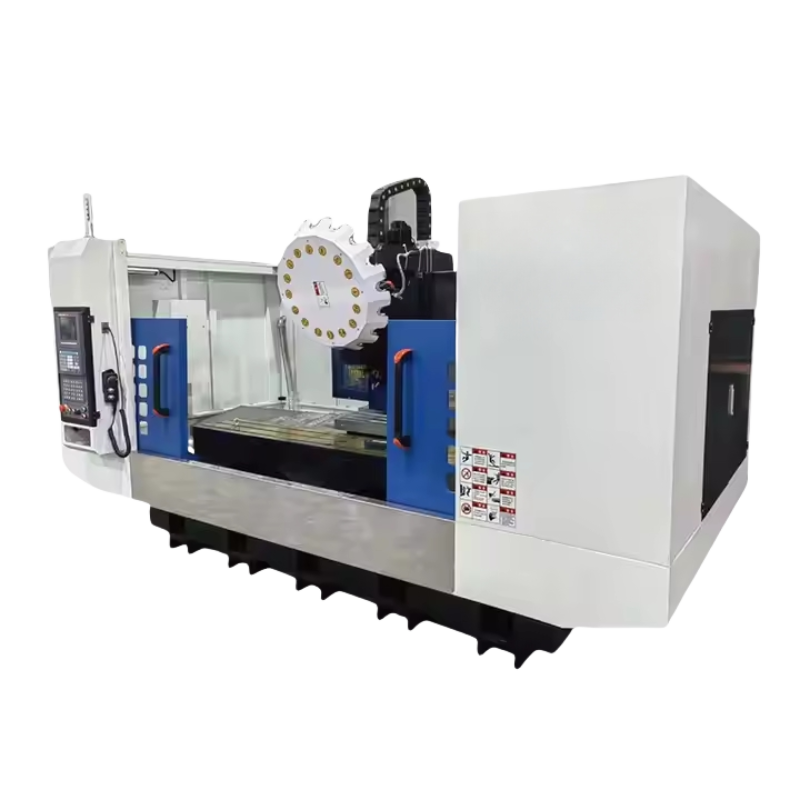

In today’s competitive manufacturing landscape, achieving unmatched precision and efficiency is no longer optional—it’s essential. For professionals seeking advanced machining solutions, the High Precision BT30 Disc Clamping Arm Tool Magazine Drilling Center Lathe Machine SCJT2000-16T stands as a transformative asset. This article explores how integrating this technology optimizes workflow, reduces downtime, and delivers superior results for workshops and small-scale production facilities.

Why Precision Matters in Modern Machining

The demand for ultra-accurate components spans industries like automotive, aerospace, and custom fabrication. Traditional lathes often struggle with consistency, especially during prolonged operations. Here, the BT30 Disc Clamping Arm system shines. Its rigid spindle interface minimizes vibration, ensuring tolerances as tight as ±0.005 mm—critical for intricate designs or high-volume repeat jobs.

Key Features Redefining Efficiency

1. High-Speed Tool Magazine Integration

Equipped with a 16-tool automatic magazine, the SCJT2000-16T slashes setup delays. Operators switch tools in seconds, eliminating manual adjustments and reducing human error. Whether drilling, milling, or threading, transitions are seamless.

2. Optimized Disc Clamping Mechanism

The BT30 Clamping Arm employs a patented disc design that distributes clamping force uniformly. This prevents tool slippage under heavy loads, maintaining positional accuracy even during aggressive cuts.

3. Enhanced Durability for Continuous Use

Constructed from hardened steel and coated with anti-wear layers, components withstand extreme temperatures and repetitive stress. Expect years of reliable service with minimal maintenance.

4. User-Centric Control Interface

Intuitive programming panels simplify operations for both novices and experts. Real-time diagnostics and adaptive feedback ensure optimal performance across materials like titanium, stainless steel, or composites.

Applications Across Industries

– Automotive Parts Manufacturing: Produce engine components with sub-micron precision.

– Aerospace Prototyping: Achieve flawless finishes on turbine blades or structural fittings.

– Custom Tooling Shops: Tackle complex geometries without sacrificing speed.

Cost Benefits You Can’t Ignore

Investing in a High Precision BT30 Drilling Center Lathe Machine translates to long-term savings. Reduced scrap rates, faster cycle times, and lower energy consumption directly boost ROI. For small businesses, this agility means competing with larger players while maintaining profit margins.

Why Choose the SCJT2000-16T Over Alternatives?

While generic lathes may promise affordability, they lack the engineered excellence of a purpose-built BT30 Tool Magazine System. Third-party tests confirm 30% faster job completion rates compared to similar models. Additionally, modular design allows future upgrades, ensuring your investment stays relevant as technology evolves.

Transform Your Workshop with BT30 Clamping Arm Technology

The High Precision BT30 Disc Clamping Arm Tool Magazine Drilling Center Lathe Machine SCJT2000-16T isn’t just equipment—it’s a strategic advantage. By prioritizing accuracy, speed, and durability, it empowers fabricators to exceed client expectations and scale operations confidently. Ready to elevate your production standards? Visit our website today to explore specifications, request a demo, or consult with our engineering team.