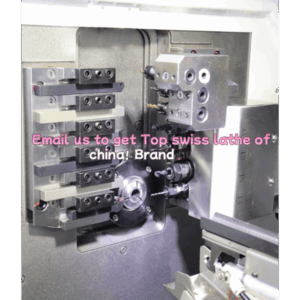

In today’s competitive manufacturing landscape, businesses demand equipment that combines speed, accuracy, and versatility. The 6-Axis φ12 Dual Motorized Spindle Swiss Lathe Machine SCJ2SL126 stands out as a cutting-edge solution engineered to meet these critical needs. Designed for precision machining of small, complex components, this advanced lathe integrates six-axis control, dual motorized spindles, and a compact φ12mm guide bushing to deliver unparalleled performance. For manufacturers seeking to optimize production workflows and elevate product quality, this machine offers a transformative edge.

Why 6-Axis Machining is the Future of Precision Engineering

The 6-Axis φ12 Dual Motorized Spindle Swiss Lathe Machine redefines multi-tasking capabilities by enabling simultaneous operations across six axes. Unlike traditional lathes limited to three or four axes, this design allows for complex geometries to be machined in a single setup. The elimination of manual repositioning reduces cycle times by up to 40% while ensuring micron-level accuracy—critical for industries like medical device manufacturing, aerospace, and automotive electronics.

Key advantages include:

– Dual Motorized Spindles: Independently controlled spindles enable concurrent front and back working, slashing idle time and boosting throughput.

– φ12mm Guide Bushing: Ideal for machining slender, high-precision parts such as surgical instruments or micro connectors.

– Adaptive Tooling: Live tooling stations support milling, drilling, and tapping without secondary operations.

Elevate Efficiency with Dual Motorized Spindle Technology

The integration of dual motorized spindles in the SCJ2SL126 model addresses a common bottleneck in Swiss-style lathes: spindle synchronization. By operating both spindles independently, manufacturers can perform simultaneous roughing and finishing tasks or handle two separate workpieces at once. This capability is particularly valuable for high-volume production runs where time savings translate directly into cost reductions.

Applications Across Industries: Where Precision Matters Most

1. Medical Device Manufacturing

From orthopedic implants to endoscopic tools, the 6-Axis φ12 Dual Motorized Spindle Swiss Lathe Machine excels in producing biocompatible components with tight tolerances (±0.001mm). Its ability to handle materials like titanium and PEEK ensures compliance with stringent regulatory standards.

2. Aerospace & Defense

Complex fuel system components and avionics housings require flawless integrity. The lathe’s six-axis control enables intricate contouring and thread milling for lightweight, high-strength alloys.

3. Electronics & Connectors

Miniaturized connectors and sensor housings demand micro-level precision. The dual spindles and live tooling adapt seamlessly to rapid design changes, making the machine ideal for prototyping and mass production.

Transform Your Production Workflow

Adopting the SCJ2SL126 Swiss Lathe isn’t just about upgrading equipment—it’s about future-proofing your operations. Features like automatic bar feeding, real-time tool monitoring, and compatibility with IoT-based predictive maintenance systems minimize downtime and maximize ROI. For small to medium-sized manufacturers, this machine bridges the gap between traditional workshops and smart factories.

Moreover, its compact footprint optimizes floor space, while energy-efficient motors align with sustainability goals. By reducing material waste and energy consumption, businesses can achieve both cost savings and greener operations.

Experience Unmatched Precision with 6-Axis φ12 Dual Motorized Spindle Swiss Lathe Solutions

The 6-Axis φ12 Dual Motorized Spindle Swiss Lathe Machine SCJ2SL126 isn’t merely a tool—it’s a strategic asset for manufacturers aiming to dominate their markets. With its six-axis agility, dual spindle efficiency, and φ12mm precision capabilities, this machine empowers businesses to tackle complex projects faster, smarter, and more reliably.

Visit our website to explore technical specifications, view live demos, or schedule a consultation with our engineering team. Let us help you turn precision into profit.