Description

12mm Vertical Manual Tapping Machine SCJT12 Series

|

Model

|

SCJT12

|

SCJT12G

|

SCJT12U

|

|

Max.Tapping

|

M3-M12 for iron/ M3-M8 for MCS/M3-M5 for SUS

|

M3-M12 for iron/ M3-M8 for MCS/M3-M5 for SUS

|

M3-M12 for iron/ M3-M8 for MCS/M3-M5 for SUS

|

|

Column diameter

|

60mm

|

60mm

|

70mm

|

|

Spindle stroke

|

40mm

|

40mm

|

50mm

|

|

Distance from spindle center to column busbar

|

127mm

|

127mm

|

195mm

|

|

Distance from spindle center to table

|

240mm

|

245mm

|

365mm

|

|

Max distance from spindle end to base

|

370mm

|

375mm

|

543mm

|

|

Tapper

|

B16

|

B16

|

B16

|

|

Spindle speed

|

260/440/750 rpm

|

260/440/750 rpm

|

260/440/750 rpm

|

|

Speed grade

|

3

|

3

|

3

|

|

Worktable

|

235*235mm

|

235*235mm

|

260*260mm

|

|

Working base

|

400*250mm

|

400*250mm

|

400*250mm

|

|

Volt

|

220/380v

|

220/380v

|

380v

|

|

Motor

|

370/550w

|

370/550w

|

550w

|

|

Weight(G.W./N.W.)

|

70/50kg

|

70/50kg

|

78/95kg

|

|

Volume

|

580*370*900mm

|

580*370*900mm

|

720*420*960mm

|

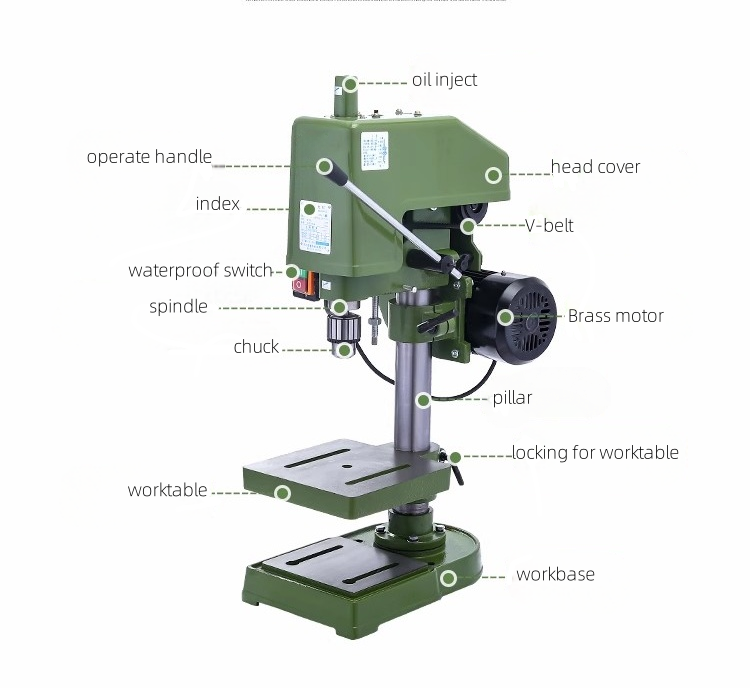

Machine Features:

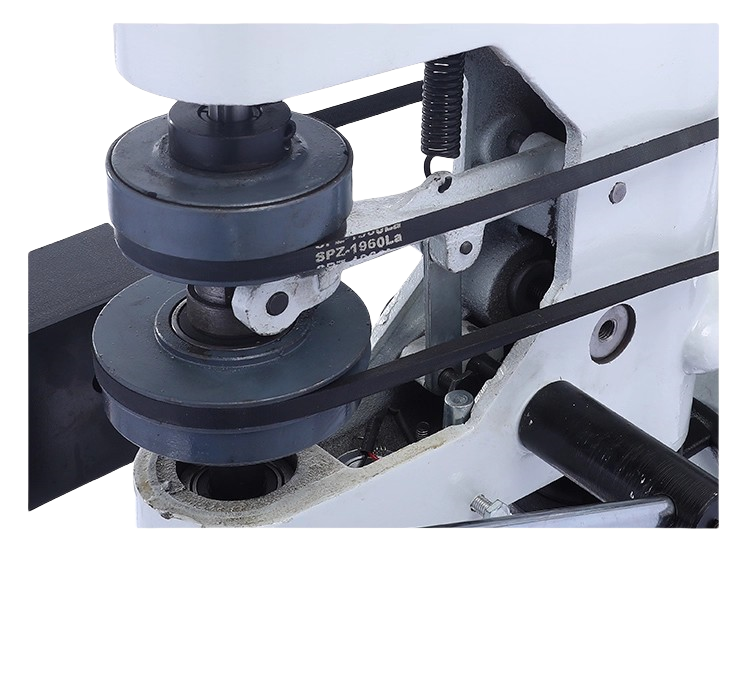

2. Mechanical friction clutch,improved clutch structure, extended handle rod, simple and easy operation, long service life

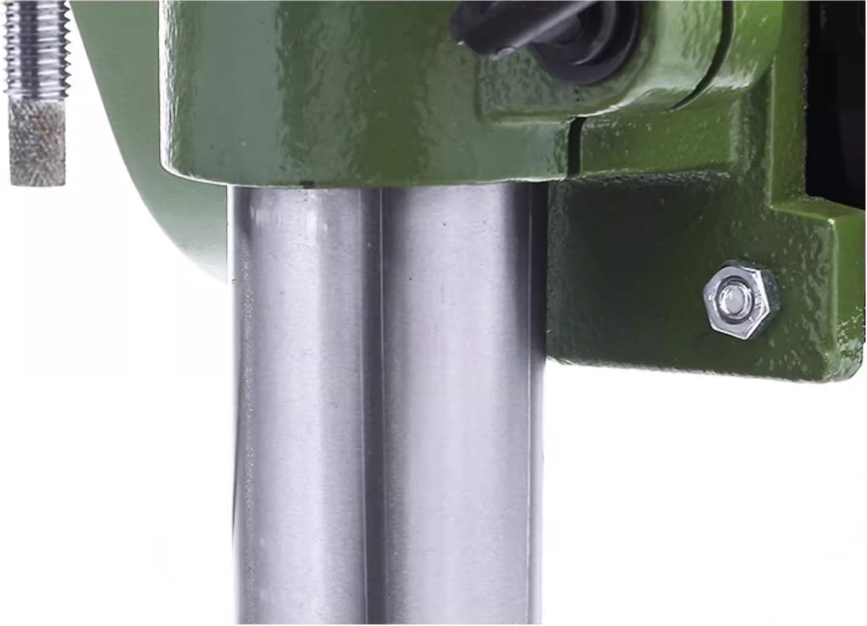

3. Bold column,the diameter of the column is thickened and high-quality steel is used for greater stability

4. High quality drill chuck,the spindle adopts precision grinding technology, combined with high-quality drill chuck, effectively improving the accuracy of the whole machine

5. Waterproof button switch,convenient and highly secure

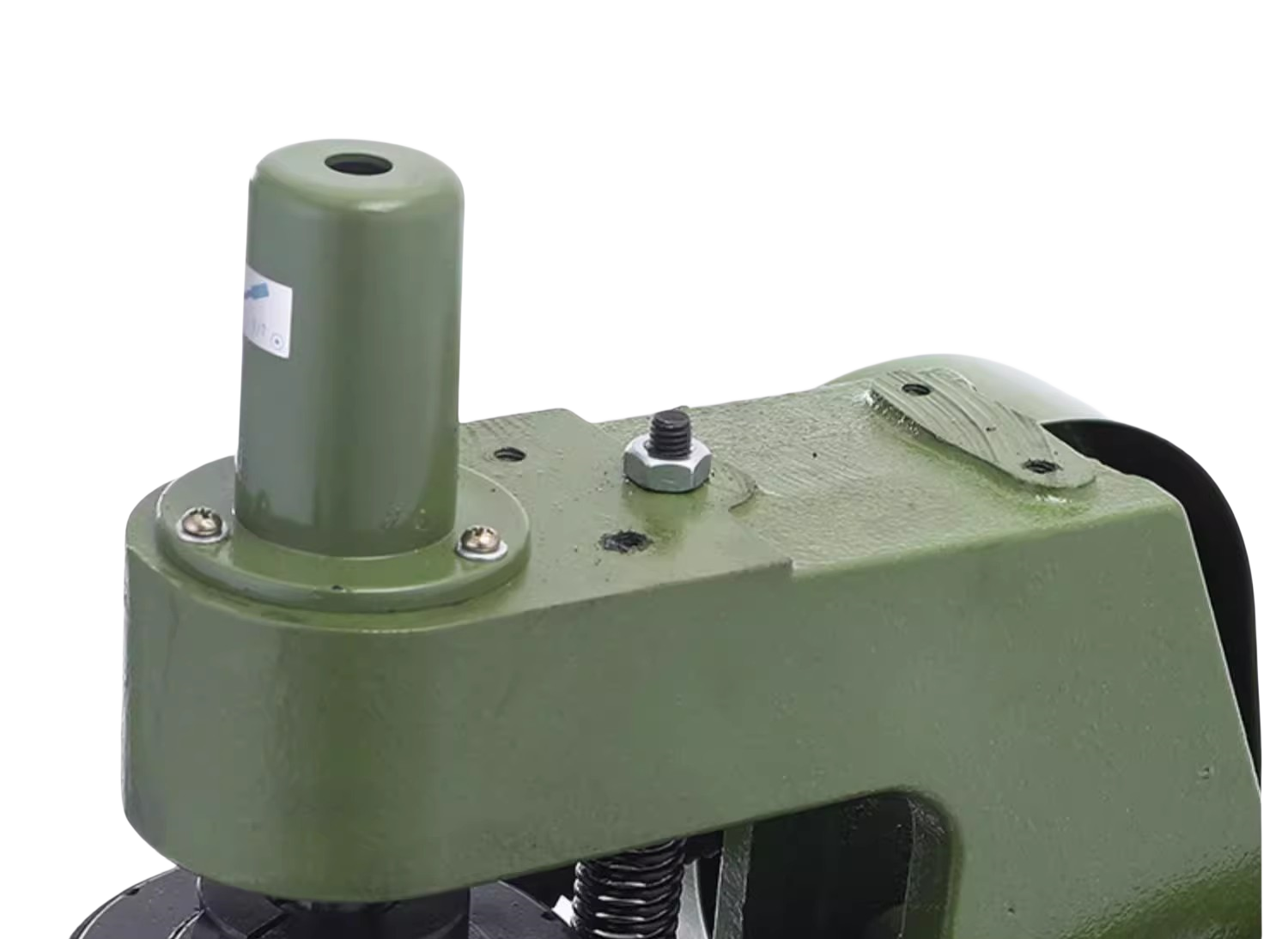

6. Spindle oil filling hole,to ensure smooth friction and disengagement of the friction wheel, lubricating oil needs to be added to the oil filling hole

Non Standard Goods:

Non standard goods refer to goods or equipment that are not made according to the work standards and specifications published by the country, but are made according to one’s own needs and plans. And if the appearance or function is not included in the national equipment product catalog, products produced, modified or customized based on user requests and standardized products are called non-standard products.

Enquiry Notice for Customerized Machine:

1. The customer provides the required parts for processing, assembly, and riveting, and clarifies a series of information about the parts, such as tolerances, burrs, deformation, etc.

2. We will conduct a series of analyses on the components provided by the customer and provide a quotation

Reviews

There are no reviews yet.