Description

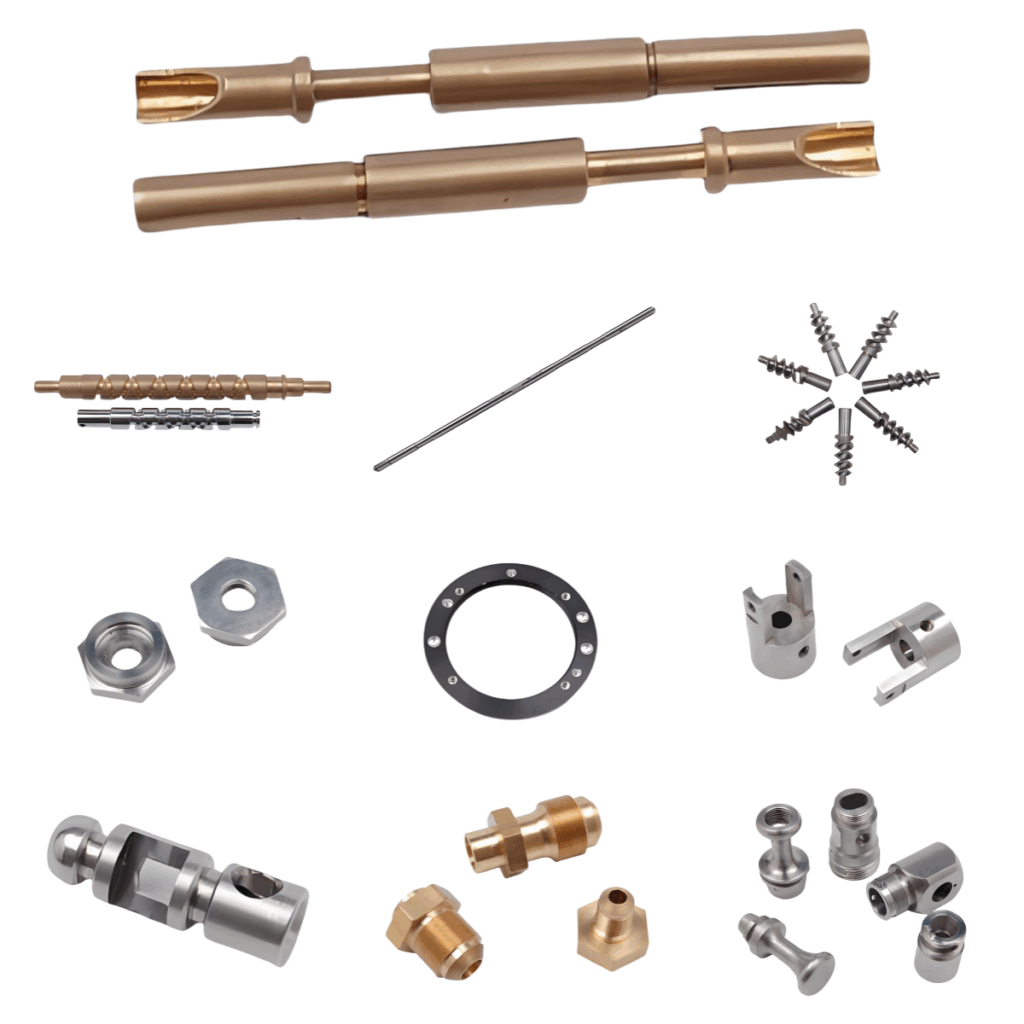

5-axis C3604 Brass Pipe Fittings for Refrigeration Equipment Twin Motorized Spindle Swiss Lathe Machine SCJ2SL385

| Model | SCJ2SL385 | ||

| Parameters | 5axis,dual spindle | ||

| NC system | FANUC Oi-TF Plus | ||

| Lathe rated power | kw | 25 | |

| Machining Range | |||

| Maximum machining diameter | mm | φ38 | |

| Maximum machining length (one-time clamping)With guide bush | mm | 320 | |

| Maximum machining length (one-time clamping)Non guide bush | mm | 85 | |

| Max tool installed qty | 21 | ||

| Main spindle power | kw | 10 | |

| sub spindle power | kw | 10 | |

| Main/sub spindle rev speed | rpm | 6000 | |

| Main spindle max through hole dia | mm | φ42 | |

| Sub spindle max clamping dia | mm | φ38 | |

| Sub spindle max through hole dia | mm | φ42 | |

| Machine Tool Information | |||

| Rapid feed speed | m/min | 18(X1) 24(X2/Y1/Z1/Z2) |

|

| Feed motor power | kw | 1.2 | |

| The power capacity | vac | 380 | |

| Air pressure device | mpa | 0.6 | |

| Weight | T | 4.5 | |

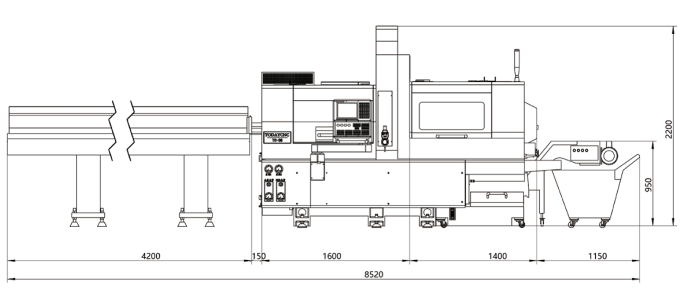

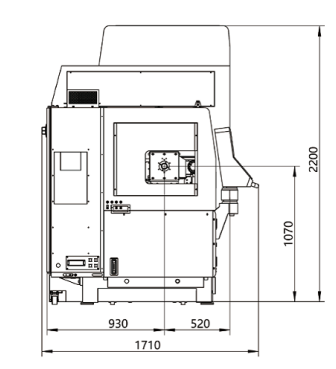

| Dimensions | mm | 3000*1450*2200 | |

Product Features:

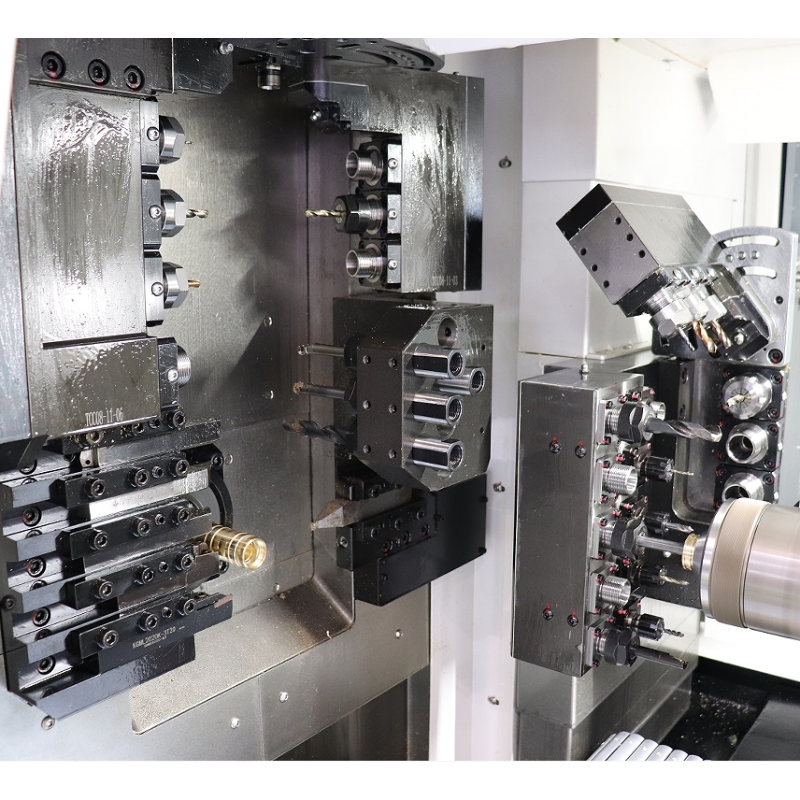

1. Each axis guide rail adopts a 30 type P-type roller guide rail and a 32 type double nut C3 level screw.

2. This machine has a built-in electric spindle and hydraulic clamping to ensure high-strength machining.

3. The spindle clamping is compatible with both forward push and backward pull clamping forms, without the need for large-diameter grinding materials.

4. The length of the spindle with guide sleeve for one-time processing is 320mm.

5. The spindle side milling adopts ER25+ER20 with 2.3 high-power motor, combined with spindle hydraulic brake, to improve milling efficiency and rigidity.

6. The spindle tool holder adopts a zigzag layout, reducing the size of the machine tool, enhancing the rigidity of the tool holder structure, and achieving fast tool changing speed.

Standard Configuration:

1. Short workpiece collector

2. Workpiece belt conveyor

3. Synchronal rotary guide bush device

4. Main spindle cross 4 axis live tool

5. Cut off tool breakage detector

6. Non guide bush

Optional Configuration:

1. Angular drilling head

2. Long workpiece collector

3. High pressure pump

4. Oil mist collector

5. Chip conveyor

6. Axial drilling and milling tool

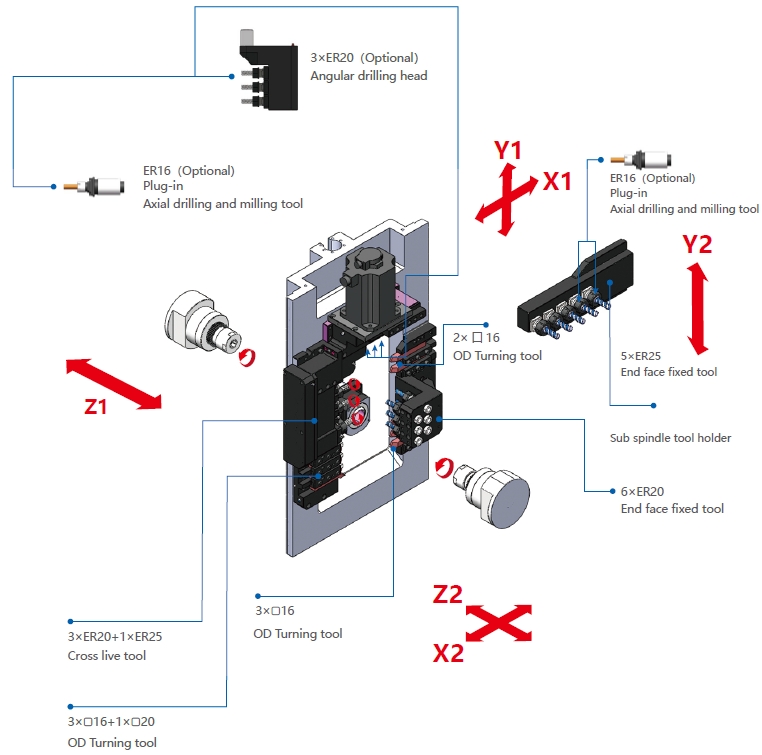

Structure

Our Package:

Reviews

There are no reviews yet.