Description

5-axis SUS404 Transmission Double Mechanical Spindle Swiss Lathe Machine SCJ2SL325M Series

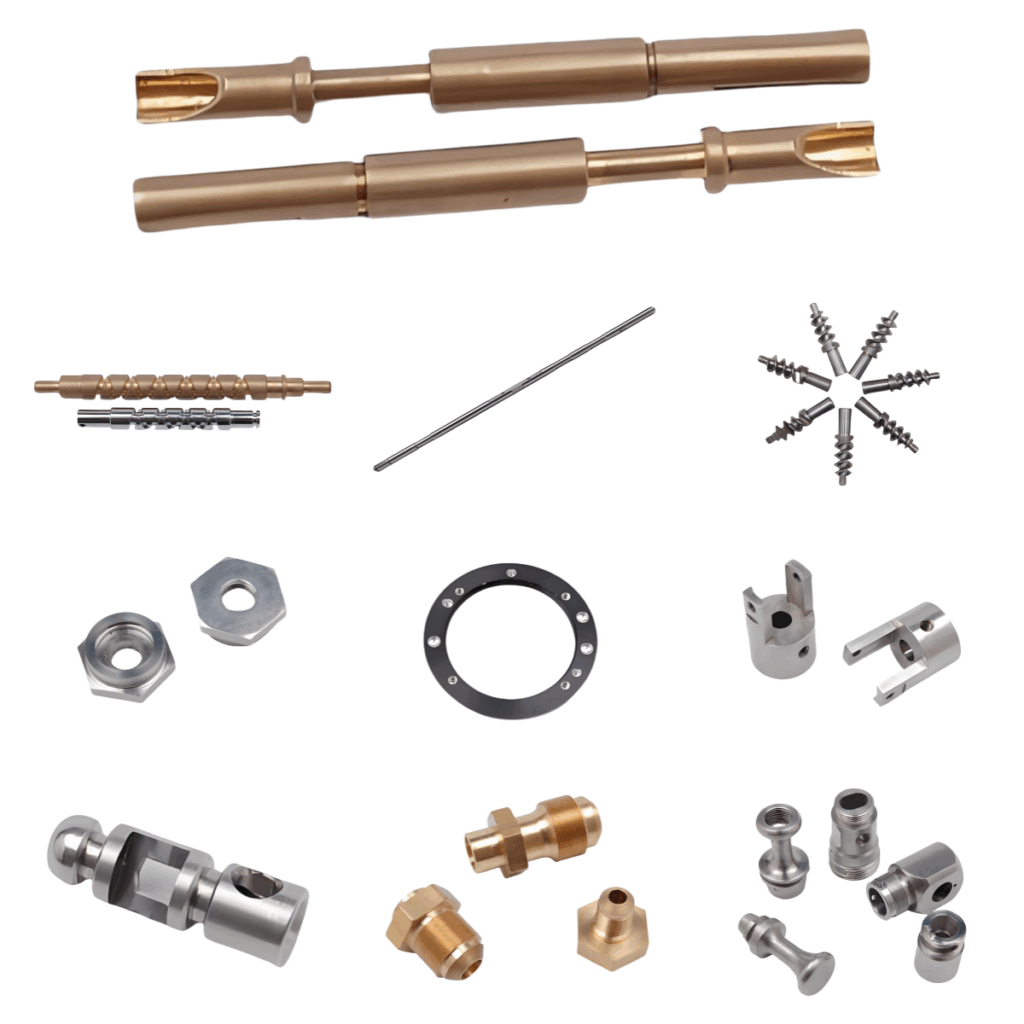

| Model | SCJ2SL325-1 | SCJ2SL325-2 | SCJ2SL325-3 | SCJ2SL325-4 | ||

| Parameters | 5axis,dual spindle | 5axis,dual spindle | 5axis,dual spindle | 5axis,dual spindle | ||

| NC system | FANUC Oi-TF Plus | FANUC Oi-TF Plus | FANUC Oi-TF Plus | FANUC Oi-TF Plus | ||

| Lathe rated power | kw | 16 | 16 | 16 | 16 | |

| Machining Range | ||||||

| Maximum machining diameter | mm | φ32 | φ32 | φ32 | φ32 | |

| With guide bush | mm | 310 | 310 | 310 | 310 | |

| Non guide bush | mm | 2D | 2D | 2D | 2D | |

| Max tool installed qty | 18 | 20 | 21 | 23 | ||

| Main/Sub Spindle | ||||||

| Main spindle power | kw | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 | |

| sub spindle power | kw | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 | 3.7/5.5 | |

| Main/sub spindle rev speed | rpm | 6000/6000 | 6000/6000 | 6000/6000 | 6000/6000 | |

| Main spindle max through hole dia | mm | φ33 | φ33 | φ33 | φ33 | |

| Sub spindle max clamping dia | mm | φ32 | φ32 | φ32 | φ32 | |

| Sub spindle max through hole dia | mm | φ33 | φ33 | φ33 | φ33 | |

| Machine Tool Information | ||||||

| Rapid feed speed | m/min | 18(X1/Y2) 24(X2/Y1/Z1/Z2) |

18(X1/Y2) 24(X2/Y1/Z1/Z2) |

18(X1/Y2) 24(X2/Y1/Z1/Z2) |

18(X1/Y2) 24(X2/Y1/Z1/Z2) |

|

| Feed motor power | kw | 0.75 | 0.75 | 0.75 | 0.75 | |

| The power capacity | vac | 380 | 380 | 380 | 380 | |

| Air pressure device | mpa | 0.6 | 0.6 | 0.6 | 0.6 | |

| Weight | T | 3.5 | 3.5 | 3.5 | 3.5 | |

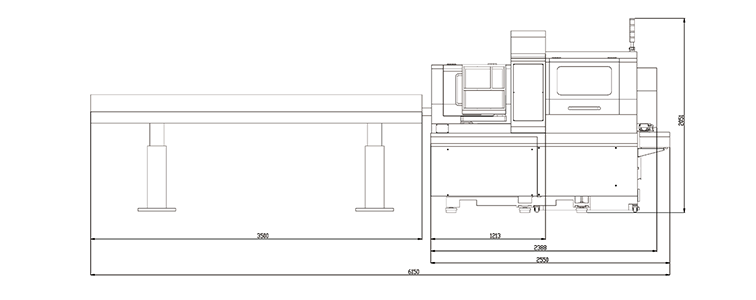

| Dimensions | mm | 2750*1500*1900 | 2750*1500*1900 | 2750*1500*1900 | 2750*1500*1900 | |

Product Features:

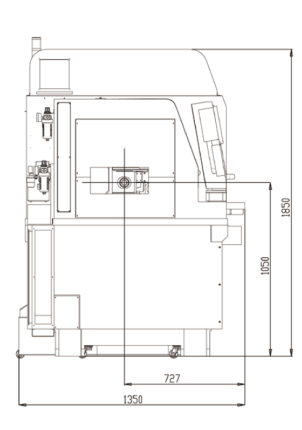

1. Each axis is equipped with imported high-precision linear guides, ball screws, and precision bearings.

2. Adopting a synchronous guide sleeve structure to achieve high-speed and high-precision machining.

3. Flexible switching between guide sleeve and non guide sleeve to meet different processing requirements.

4. The key components include gas sealed structures, which prevent oil and slag, improve service life and stability.

5. Selecting high torque motors, high rigidity and strength axial sliding tables, and tool mounting seats to meet large cutting volumes and high processing efficiency.

6. High scalability, tool quantity configuration based on process matching, high cost-effectiveness.

7. Multiple ER20 large cutting tools can be equipped to enhance the machining range.

Standard Configuration:

1. SYNTEC numerical control system

2. Main pneumatic chucking device

3. Movable guide bush

4. Synchronal rotary guide bush device

5. Live tool

6. Workpiece belt conveyor

Optional Configuration:

1. Non guide bush

2.MITSUBISHI numerical control system

3. FANUC numerical control system

4. High pressure pump

5. Oil mist collector

6.Chip conveyor

7. Long workpiece collector

8. Y2 tool holder

Structural:

Our Package:

Reviews

There are no reviews yet.