Description

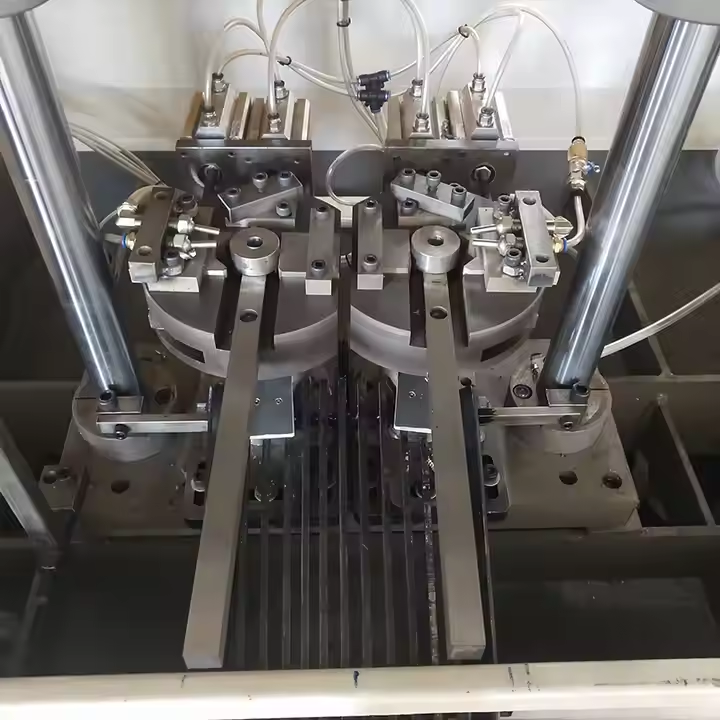

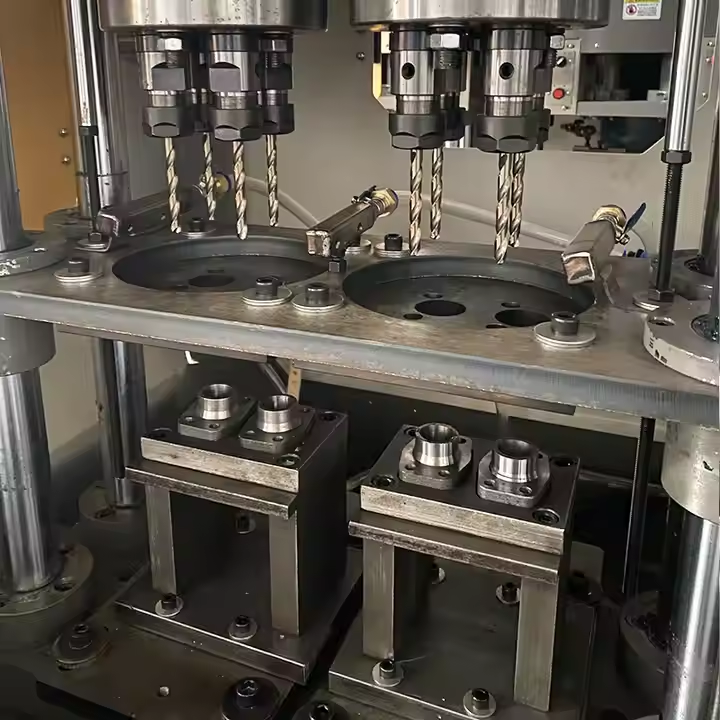

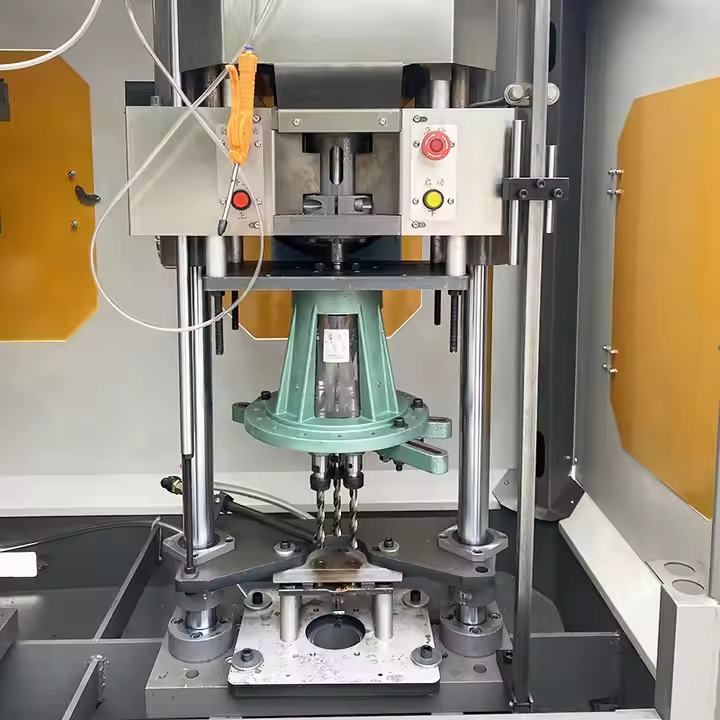

Drill Dia 20-100mm Hydraulic Single-Edge Deep Hole Drilling Machine SCJDHD Series

| Model | SCJDHD40 | SCJDHD60 | SCJDHD80 | SCJDHD100 |

| Workstation | 1-2 | 1-2 | 1-4 | 1-4 |

| Max.Drilling Dia | 10-40mm | 20-60mm | 30-80mm | 70-100mm |

| Cooling System | 750w | 750w | 750w | 750w |

| Linear column | 50*4 | 60*4 | 80*4 | 80*4 |

| Maximum spindle stroke | 400mm | 500mm | 600mm | 600mm |

| Spindle | 40 Axis | 40 Axis | 50 Axis | 50 Axis |

| Main spindle to working table | 600mm | 450mm | 700mm | 300-650 |

|

Spindle speed

|

750-1500r/min

|

400-1500r/min

|

400-950r/min

|

300-650r/min

|

| Table size | 400*400mm | 500*500mm | 600*600mm | 600*600mm |

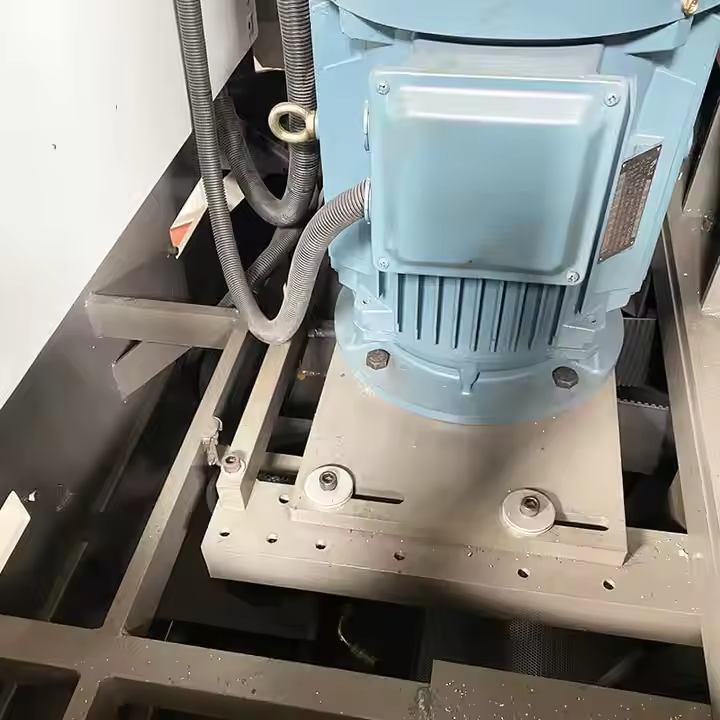

| Spindle motor | 15kw | 18.5kw | 22kw | 30kw |

| Oil Pump motor | 1.5kw | 1.5kw | 1.5kw | 1.5kw |

| Voltage | 380V | 380V | 380V | 380V |

| Frequency | 50HZ | 50HZ | 50HZ | 50HZ |

| Volume | 1700*1900*2700mm | 1700*1900*2700mm | 1850*2000*2850mm | 1850*2000*2850mm |

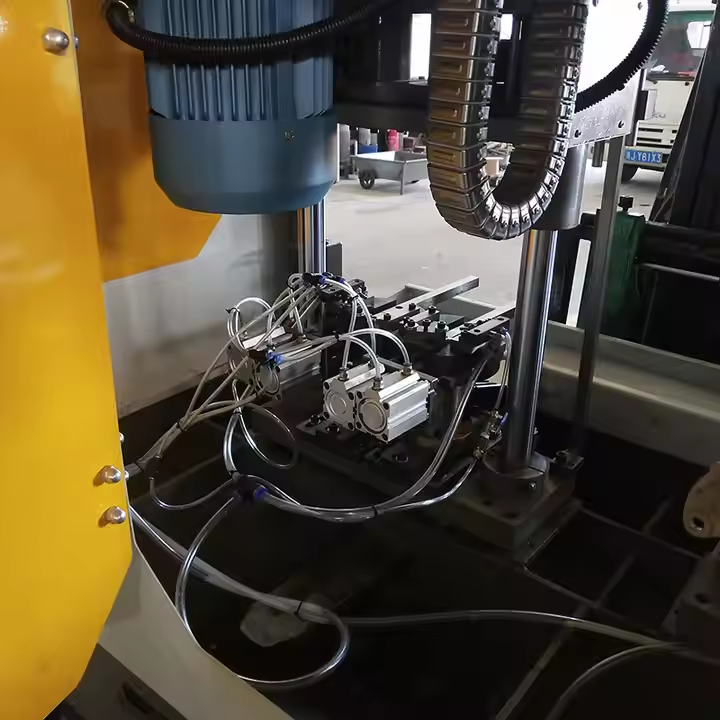

Machine Features:

A deep hole drill is a tool specially used for processing deep holes. It is often used to process holes with a large depth, usually with a high ratio of depth to hole diameter. The main feature of a deep hole drill is that it can maintain a high drilling depth at a small drill diameter, and is suitable for processing scenarios that require precise control of hole diameter and depth.

1. Suitable for deep hole processing

2. Strong cutting stability

3. High precision requirements

4. Efficient chip removal system

5. Special drill design

6. Low feed speed

7. High cooling and lubrication requirements

8. Wide range of applicable materials

9. Large processing depth to diameter ratio

10. Customized requirements

Non Standard Goods:

Non standard goods refer to goods or equipment that are not made according to the work standards and specifications published by the country, but are made according to one’s own needs and plans. And if the appearance or function is not included in the national equipment product catalog, products produced, modified or customized based on user requests and standardized products are called non-standard products.

Enquiry Notice for Customerized Machine:

1. The customer provides the required parts for processing, assembly, and riveting, and clarifies a series of information about the parts, such as tolerances, burrs, deformation, etc.

2. We will conduct a series of analyses on the components provided by the customer and provide a quotation

Reviews

There are no reviews yet.