Description

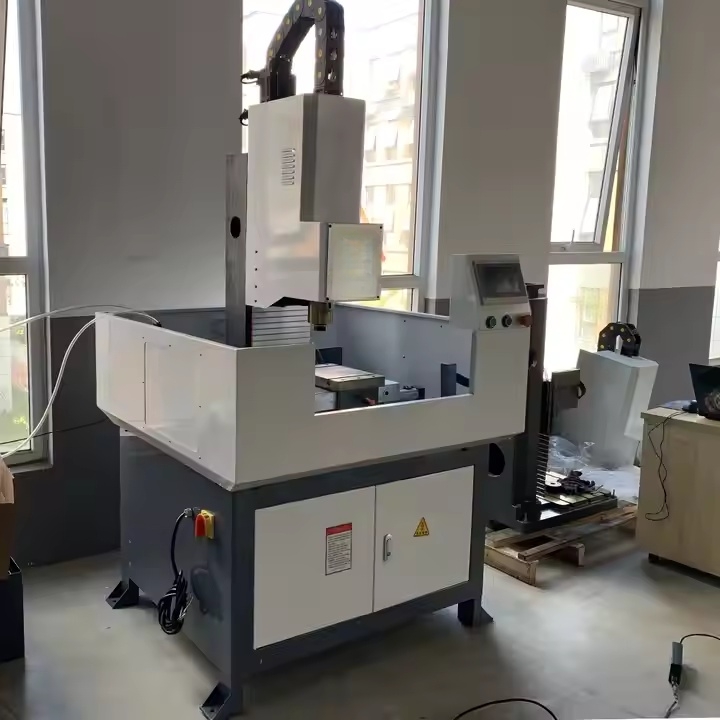

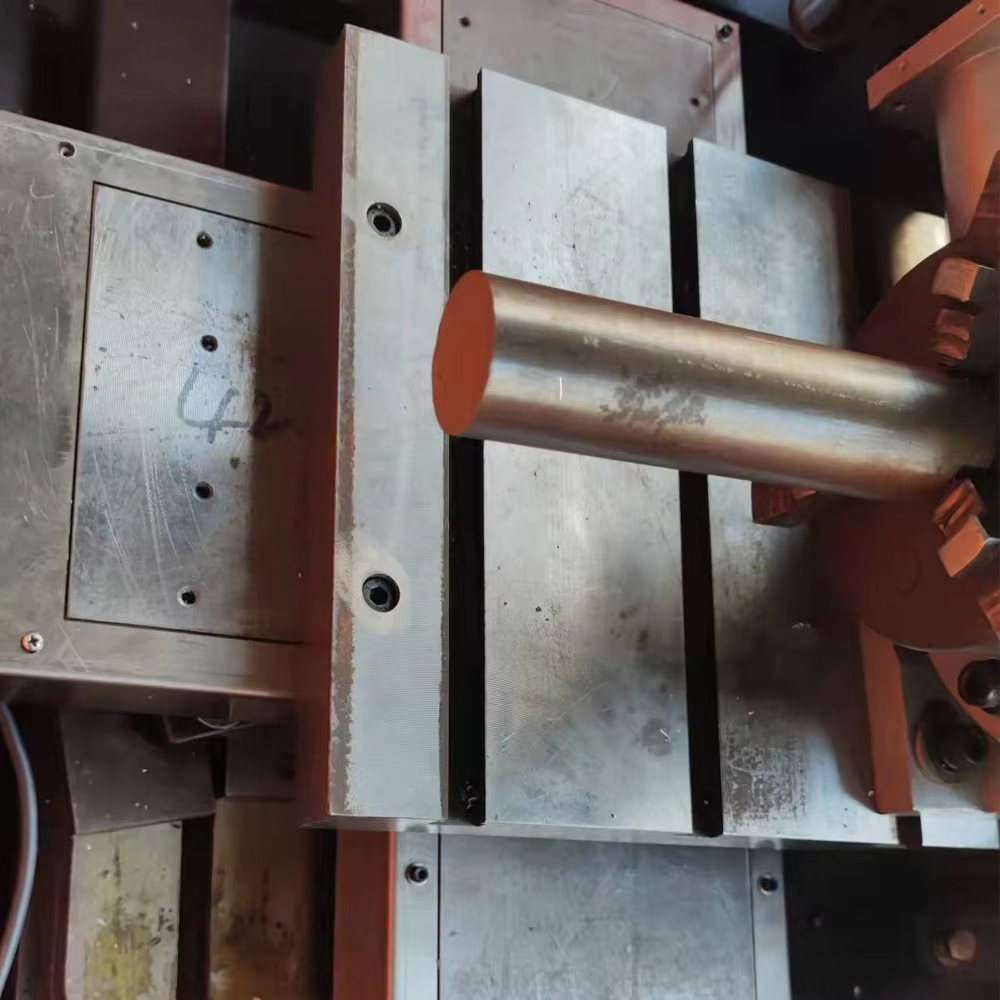

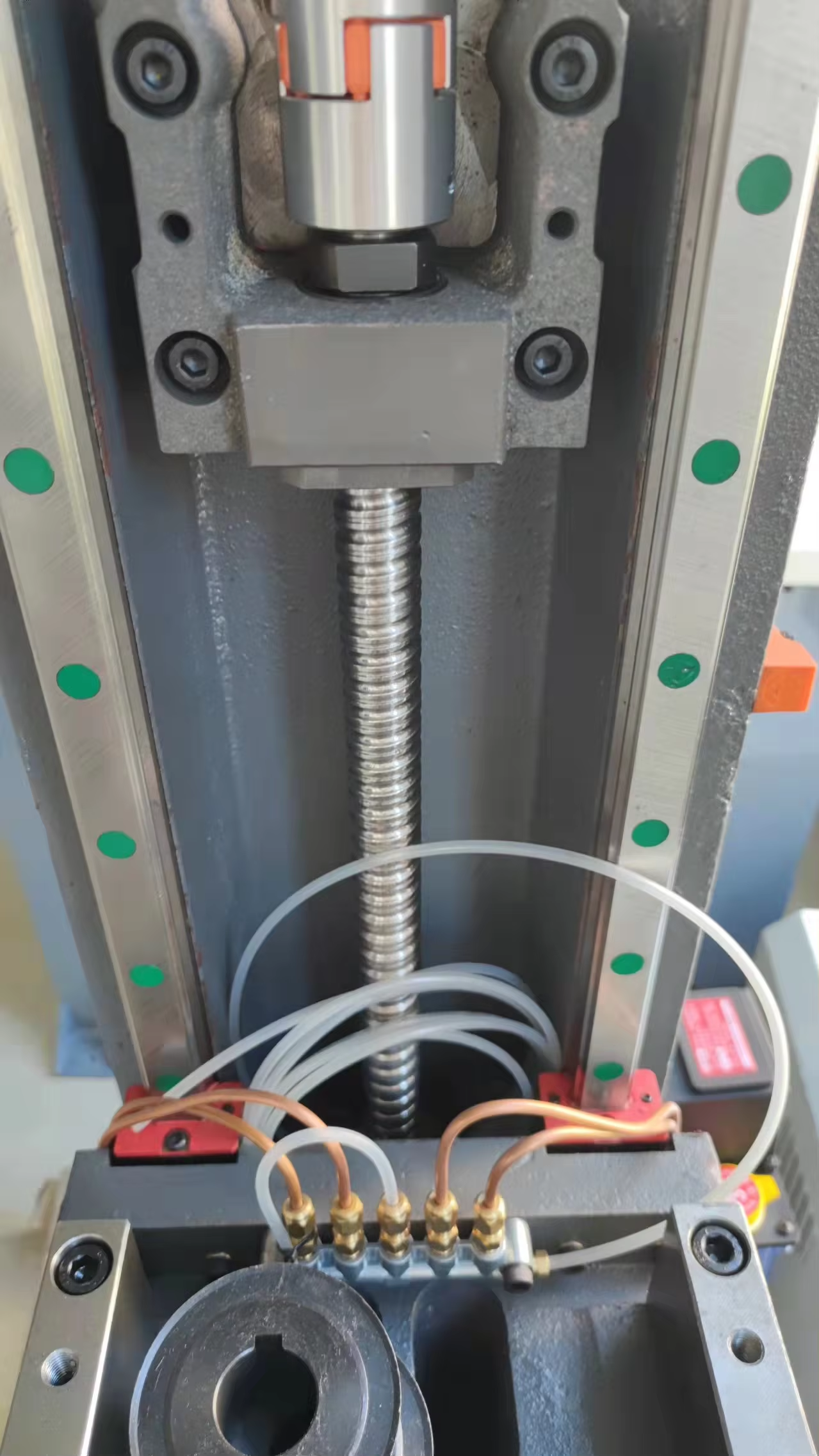

3 Axis CNC Chamfering Drilling Tapping Machine With Servo Motor SCJCDT30F

|

Model

|

SCJCDT30F(single servo)

|

SCJCDT30F-D(double servo)

|

|

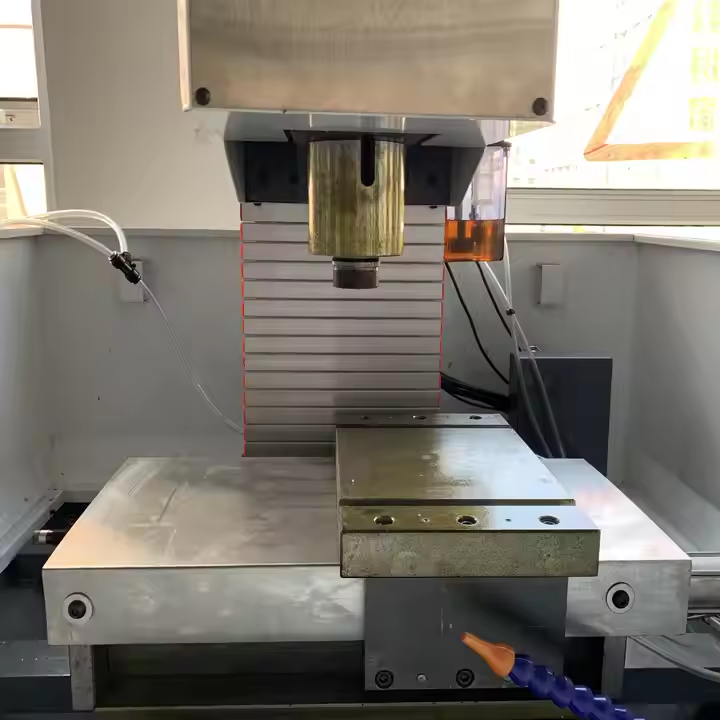

Drilling capacity(mm)

|

30mm/MT24

|

30mm/MT24

|

|

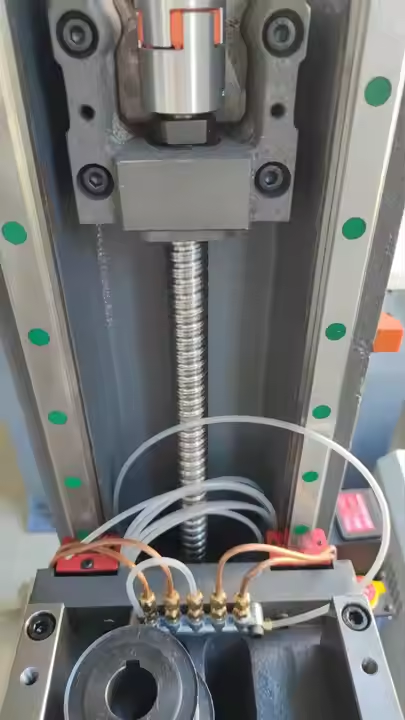

Spindle travle(mm)

|

200

|

200

|

|

Spindle head to table(mm)

|

300-500

|

300-500

|

|

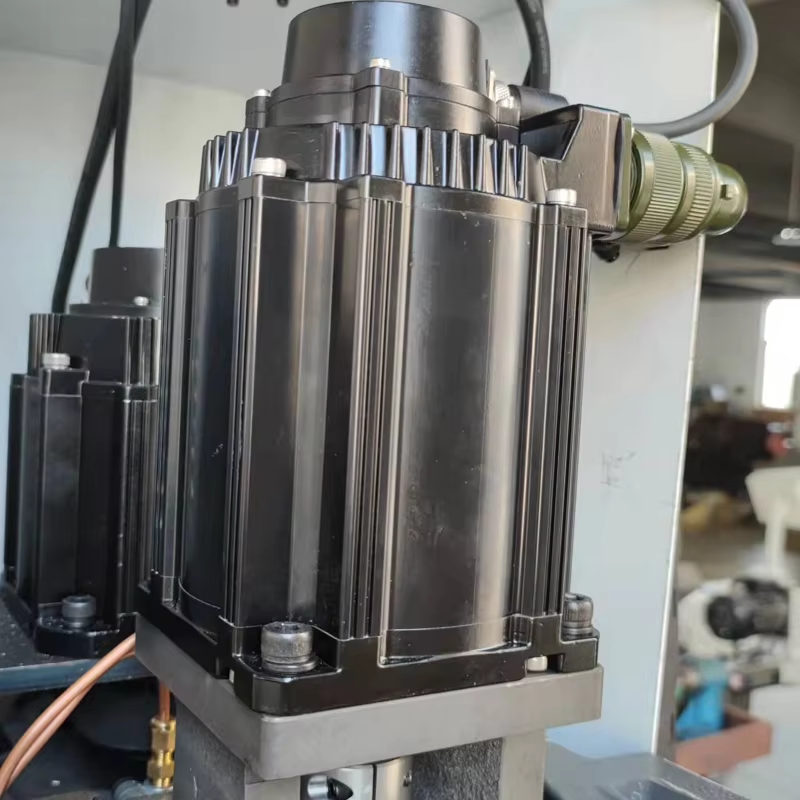

Sevro motor

|

1.2kw

|

1.2kw

|

|

Taper

|

MT3

|

MT3

|

|

Spindle speed(r/min)

|

1600

|

100-3000

|

|

Working table

|

400*400mm

|

400*400mm

|

|

Column Size

|

240*150*900mm

|

240*150*900mm

|

|

Spindle Motor

|

3kw

|

2.6kw

|

|

Weight(kg)

|

550

|

550

|

Machine Features:

2.High precision: This machine uses advanced CNC technology to accurately control the parameters of each processing step, such as drilling depth, tapping depth, chamfering angle, etc.

3.High stability: The design of the drilling, tapping and chamfering machine focuses on stability and durability.

4.Saving space: Due to the integration of multiple processes, the drilling, tapping and chamfering machine occupies a smaller area than traditional separate equipment, saving production space and making the layout of the factory or workshop more compact and reasonable.

5.Reduce labor intensity: The machine has a high degree of automation, which reduces the need for manual operations, reduces the labor intensity of workers, and improves production safety at the same time.

6.Improve product quality: Due to the use of automation and CNC technology, the drilling, tapping and chamfering machine can ensure the consistency and stability of the processing process, thereby improving product quality.

7.Flexibility: The drilling, tapping and chamfering machine can be flexibly configured and adjusted according to different processing needs, adapting to the processing requirements of different materials, different sizes and different processes.

Non Standard Goods:

Non standard goods refer to goods or equipment that are not made according to the work standards and specifications published by the country, but are made according to one’s own needs and plans. And if the appearance or function is not included in the national equipment product catalog, products produced, modified or customized based on user requests and standardized products are called non-standard products.

Enquiry Notice for Customerized Machine:

1. The customer provides the required parts for processing, assembly, and riveting, and clarifies a series of information about the parts, such as tolerances, burrs, deformation, etc.

2. We will conduct a series of analyses on the components provided by the customer and provide a quotation

Reviews

There are no reviews yet.