Description

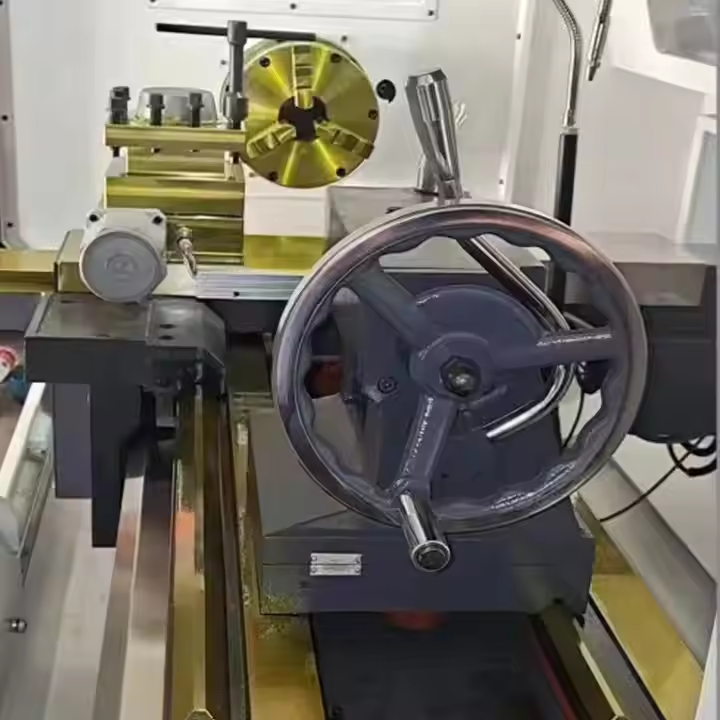

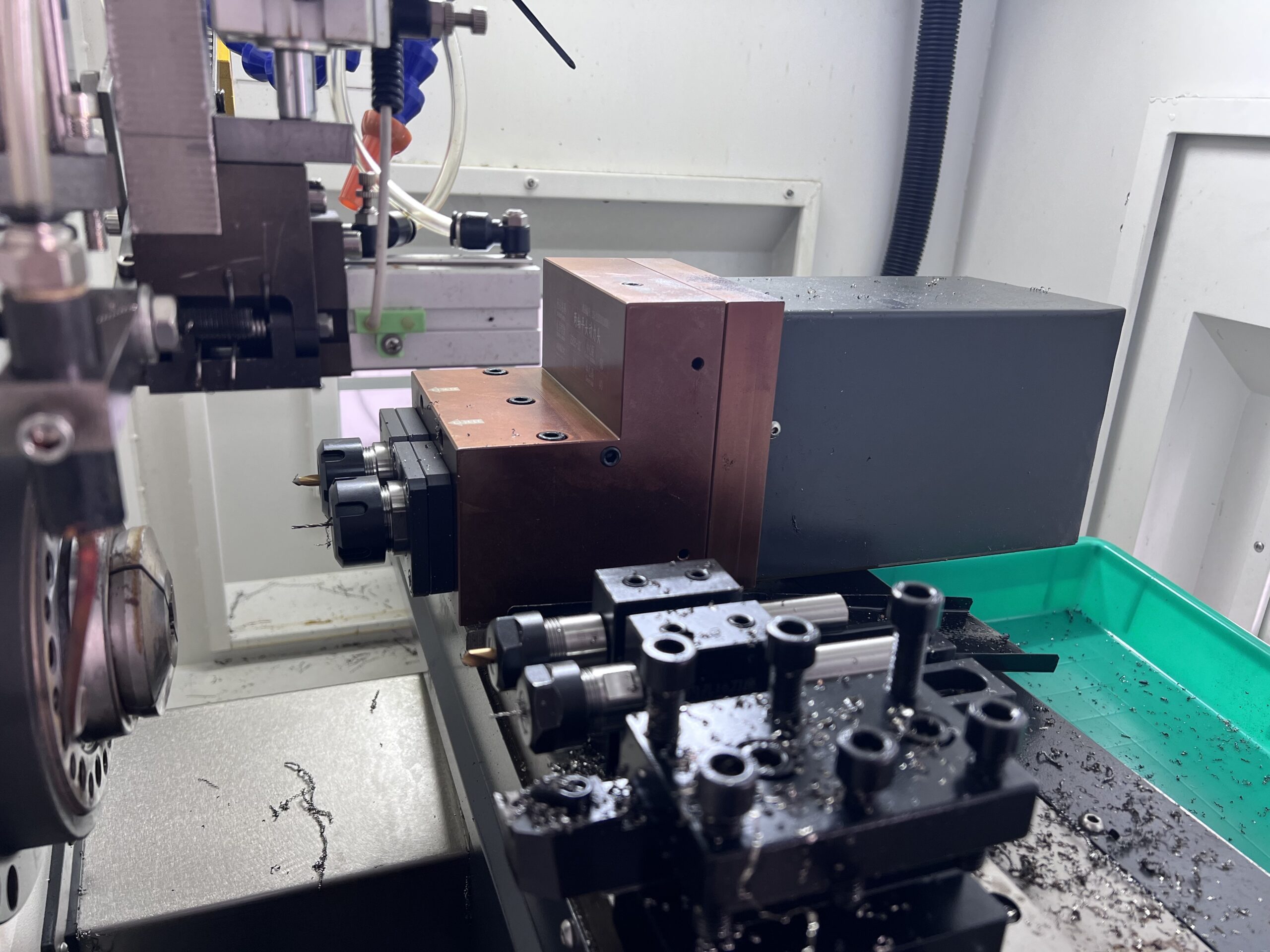

High Precision Machine Tool High Speed Wire Rail CNC Lathe Machine

Machine Features:

1.High precision: The CNC lathe machine adopts a high-precision CNC system, which can accurately control the movement of the machine tool to ensure the processing accuracy. This enables it to produce high-precision parts and meet the high requirements of modern manufacturing industry for product quality.

2.High efficiency: The CNC lathe can automatically complete complex processing tasks, greatly reducing manual intervention and improving production efficiency. In addition, due to its high precision and high efficiency, it can reduce the scrap rate in the production process and further improve production efficiency.

3.Flexibility: The CNC lathe has strong flexibility and can adjust the machine parameters and programs according to different processing requirements to achieve a variety of processing tasks. This enables it to adapt to various production needs and meet the personalized needs of customers.

4.Easy maintenance: The CNC lathe has a complete fault detection and alarm system, which can detect and eliminate faults in time. At the same time, its maintenance and maintenance are relatively simple, reducing maintenance costs.

5.High degree of automation: The CNC lathe has a high degree of automation in the processing process. Except for blank processing and clamping, most processing tasks can be completed automatically by the machine tool, reducing the labor intensity of workers and improving work efficiency.

6.Strong adaptability: When the processing object changes, the CNC lathe only needs to change the program to meet the new processing requirements, without the need to redesign the tooling, which greatly saves production preparation time.

7.Convenient production management: CNC machine tool processing parts can accurately calculate the processing time of parts, and simplify the inspection and management of fixtures and semi-finished products, which is conducive to the modernization of production management.

Applications:

Manufacturing: Producing cylindrical parts such as shafts, pins, and bushings.

Repair: Used in maintenance for repairing worn-out parts.

Prototyping: Essential for creating prototypes and custom components.

Woodworking: Shaping wood for furniture and decorative items.

|

ITEM

|

UNIT

|

SCJ0640

|

|

Spindle Speed

|

r/min

|

0-5000

|

|

Dia of bed rotation

|

mm

|

400

|

|

Rotary dia of support plate

|

mm

|

150

|

|

Rotary dia of row cutter plate

|

mm

|

90

|

|

Dia of spindle through hold

|

mm

|

48

|

|

Max stroke of X axis

|

mm

|

300

|

|

Max stroke of Z axis

|

mm

|

350

|

|

Fast feed rate(X and Z)

|

mm/min

|

20000

|

| Max. swing over bed |

mm

|

400

|

|

max. length of workpiece (mm)

|

mm

|

400

|

| voltage |

–

|

220V/380V,50HZ

|

| number of axes |

–

|

3

|

| no. of spindles |

–

|

4

|

| max. weight of workpiece |

kg

|

200

|

| spindle motor power |

kw

|

3/4/5.5

|

| width of bed |

mm

|

290

|

| Chuck |

–

|

3 Jaw Chuck

|

|

Positioning accuracy

|

mm

|

±0.003

|

|

Repeat positioning accuracy

|

mm

|

±0.003

|

|

Control System

|

–

|

GUANG TAI/SYNTEC/ |

|

Floorspace(L*W*H)

|

mm

|

1650*1350*1750

|

|

Machine Weight(Gross)

|

kg

|

1100

|

Reviews

There are no reviews yet.