Description

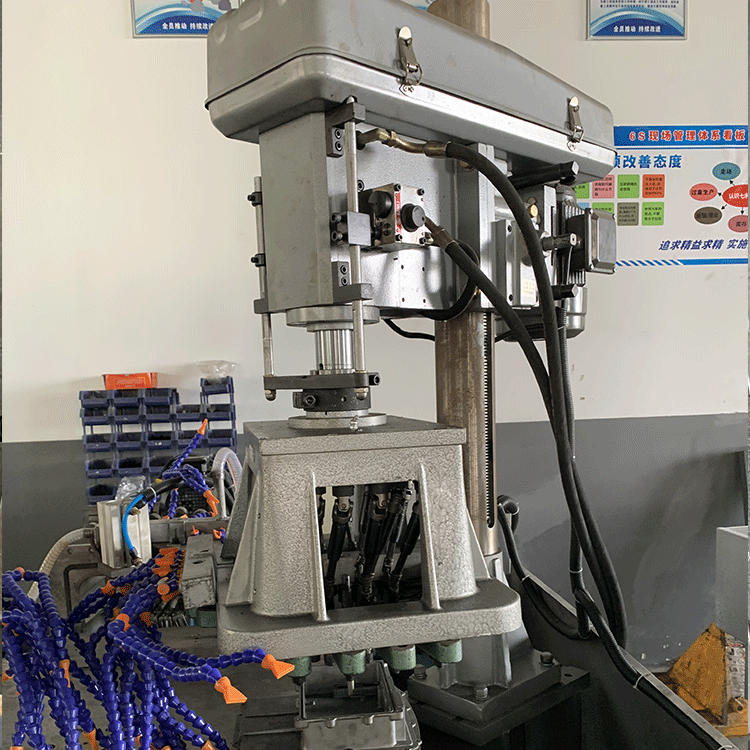

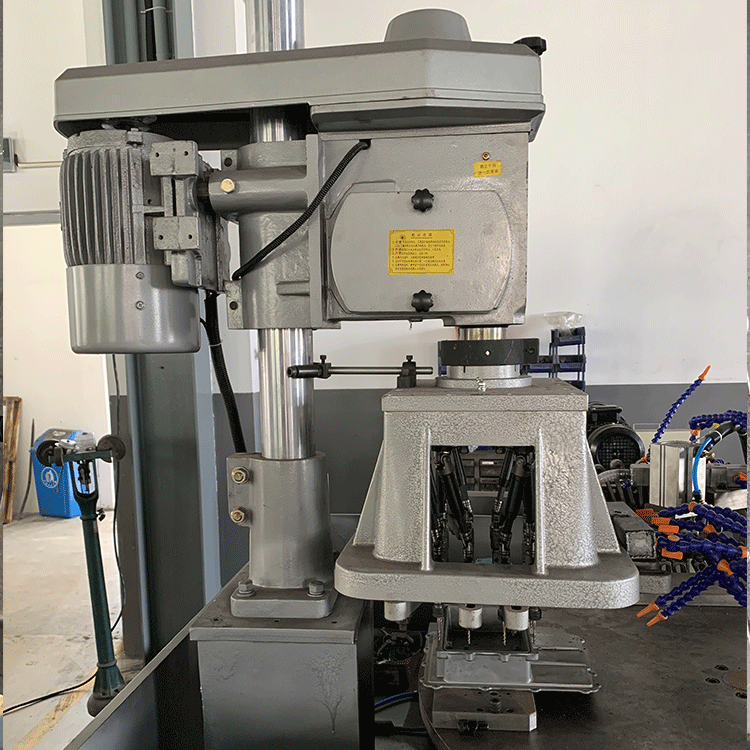

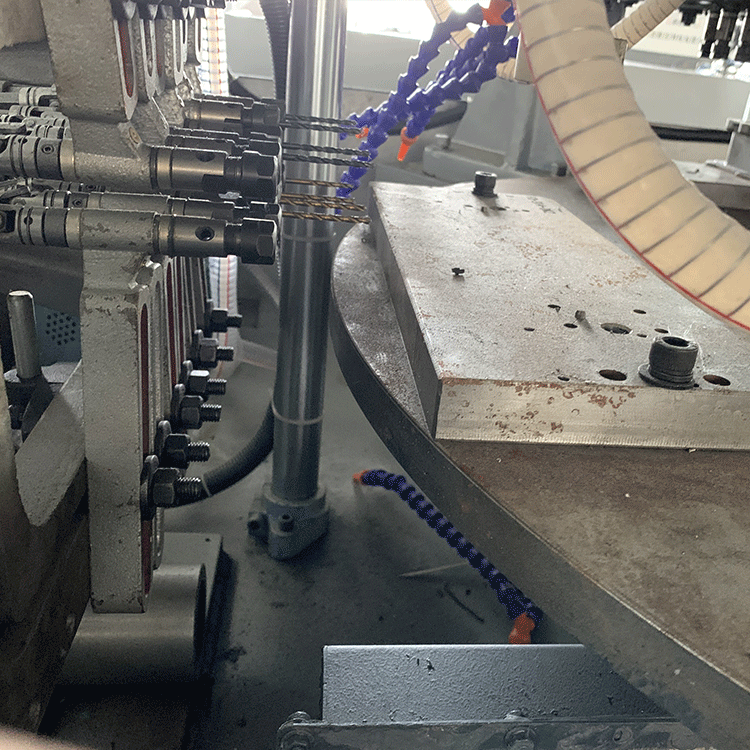

Aluminum Heat Sinks Mulit Spindle Drilling Tapping Connecting Machine SCJMS1

|

Type

|

Customzied Drilling and Tapping Machine

|

|

Model Number

|

SCJMS1

|

|

Core Components

|

Bearing, Pump, Gear, motor, Gearbox, PLC, Pressure vessel, Engine

|

|

Max. Drilling Dia. (mm)

|

Based on actual case

|

|

Drilling Speed

|

Based on actual case

|

|

Voltage

|

220V/380V

|

|

Dimension(L*W*H)

|

Based on actual case

|

|

Power (kW)

|

Based on actual case

|

|

Warranty

|

1 Year

|

|

Feature

|

Mulit Function;One-stop Processing ;Save Manpower; High Efficiency

|

|

Max. drilling diameter

|

Based on actual case

|

|

Precision

|

High Precision

|

|

Machine type

|

CNC Servo Auto

|

|

After-sales Service Provided

|

Online Support Video Technical Support

|

Machine Features:

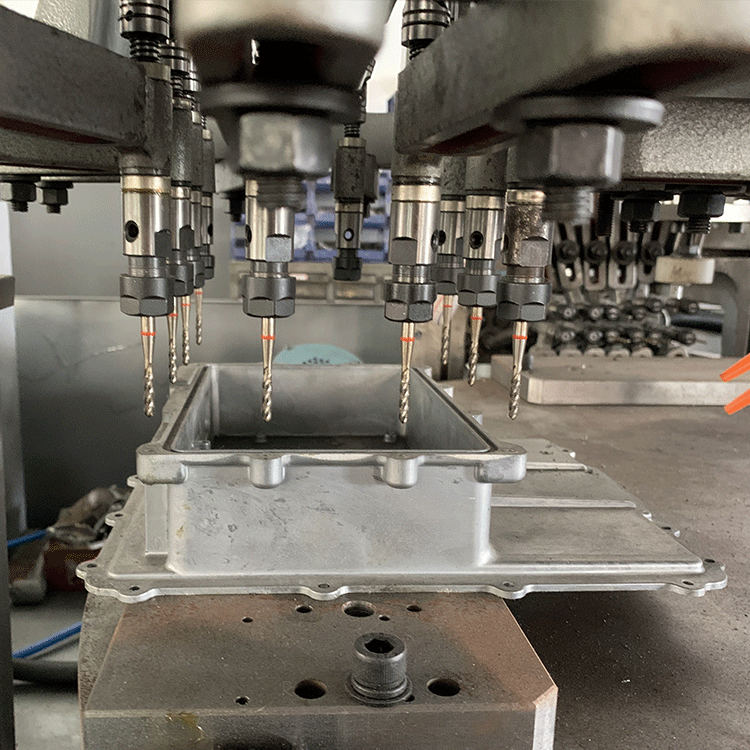

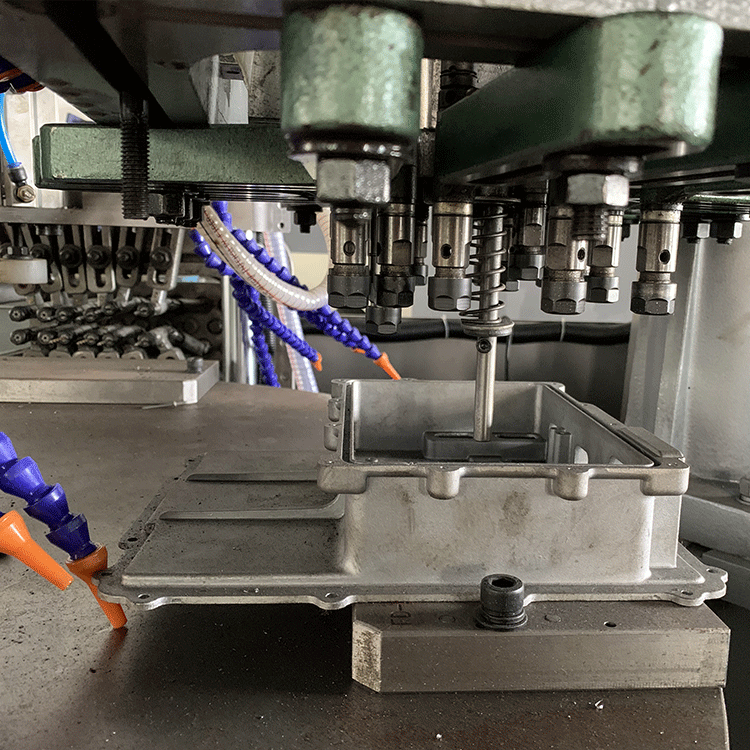

1.Improve production efficiency: The drilling tapping connecting machine integrates the two functions of drilling and tapping, and can complete two operations at one time, thus greatly reducing processing time.

2.Improve processing accuracy and stability: Drilling and tapping integrated machines usually use CNC technology, which can accurately control the depth, speed and intensity of drilling and tapping, ensuring the stability of the processing process and the accuracy of the processing results. This is especially important for industries that require high-precision machining.

3.Reduce the equipment footprint: Because the drilling and tapping all-in-one machine integrates two functions, it can greatly reduce the equipment footprint compared to traditional separate equipment.

4.Reduce labor costs: The drilling and tapping integrated machine has a high degree of automation, which can reduce dependence on operating workers.

5.High safety: The integrated drilling and tapping machine has an automatic tool return and exit function during processing. Even when tapping blind hole threads, the drill bit and tap are not easy to break.

6.Wide scope of application: The integrated drilling and tapping machine is not only suitable for processing metal materials, but can also be used for processing various materials such as wood and plastics.

Non Standard Goods:

Non standard goods refer to goods or equipment that are not made according to the work standards and specifications published by the country, but are made according to one’s own needs and plans. And if the appearance or function is not included in the national equipment product catalog, products produced, modified or customized based on user requests and standardized products are called non-standard products.

Enquiry Notice for Customerized Machine:

1. The customer provides the required parts for processing, assembly, and riveting, and clarifies a series of information about the parts, such as tolerances, burrs, deformation, etc.

2. We will conduct a series of analyses on the components provided by the customer and provide a quotation

Reviews

There are no reviews yet.