Description

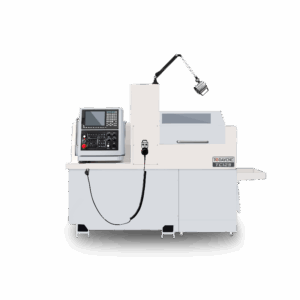

BT40 12000rpm Heavy Duty Drilling And Machining Center 3 Axia Lathe Machine SCJV600-20T

Machine Features:

1. The machine tool is made of resin sand precision casting,with large span herringbone column for stable support and after the second artificial aging treatment to ensure the rigidity of the machine tool.

2. Adopting servo tool magazine which can select tool at will,high efficiency and quick,tool change time is 1.20 seconds.

3. Adopting medium-low speed and high torque spindle motor,which improves the processing performance of copper and aluminum parts on the basis of being able to do punching and tapping of various materials.

4. The machine adopts direct-connected spindle,which improves the drilling and tapping efficiency of the spindle.

5. Three-axis high-speed displacement up to 48m/min,fast speed,saving processing time.

6.Equipped with TN46(BT40-MEDIUM 120) ,spindle,drilling,tapping and cutting performance is more excellent than BT30 spindle.Bearing rigidity is 35-40kgf,40% higher than BT30

Benefits:

Precision: High accuracy in producing complex shapes and dimensions.

Versatility: Capable of performing a wide range of operations with different tools.

Efficiency: Reduces material waste and enhances productivity through automation (in CNC lathes).

Durability: Built to withstand rigorous use in industrial environments.

Main Components:

Bed: The foundation that supports the machine and absorbs vibrations.

Headstock: Contains the motor and spindle, which holds and rotates the workpiece.

Tailstock: Supports the other end of the workpiece and can hold tools for drilling.

Carriage: Holds the cutting tool and moves it along the workpiece.

Cross Slide: Allows for lateral movement of the cutting tool.

Cutting Tools:

Various cutting tools can be mounted for turning, facing, drilling, and threading operations.

Speed Control:

Adjustable spindle speeds to accommodate different materials and cutting operations.

Feed Mechanism:

Allows for manual or automatic feeding of the cutting tool along the workpiece.

Applications

Manufacturing: Producing cylindrical parts such as shafts, pins, and bushings.

Repair: Used in maintenance for repairing worn-out parts.

Prototyping: Essential for creating prototypes and custom components.

Woodworking: Shaping wood for furniture and decorative items.

|

ITEM

|

UNIT

|

SCJV600-20T

|

|

Size of working table (L*W)

|

mm

|

700*420

|

|

T-slot (number of slots*slot width*slot)

|

mm

|

3*14*125

|

|

Maximum table load

|

kg

|

250

|

|

Maximum travel(X*Y*Z)

|

mm

|

600*400*300

|

|

Distance from spindle nose to table surface

|

mm

|

150~450 / high model: 300-600

|

|

Rapid traverse speed (X*Y*Z)

|

mm/min

|

48*48*48

|

|

Feed speed(X*Y*Z)

|

mm/min

|

10000

|

|

Spindle taper hole specification

|

–

|

BT40

|

|

Maximum spindle speed

|

rpm

|

8000/12000

|

|

Spindle drive mode

|

–

|

direct connection

|

|

Tool magazine type

|

–

|

Disc clamping arm type

|

|

Tool shank type

|

–

|

BT40

|

|

Maximum number of tools

|

PCS

|

20T

|

|

Max. tool diameter

|

mm

|

φ100

|

|

Max. tool diameter (without propper)

|

mm

|

φ140

|

|

Max. tool length

|

mm

|

250

|

|

Max. tool weight

|

kg

|

3

|

|

Tool change time (T to T)

|

sec

|

1.6

|

|

Positioning accuracy

|

mm

|

±0.005/300

|

|

Repeat positioning accuracy

|

mm

|

±0.003/300

|

|

Spindle servo motor

|

kw

|

5.5

|

|

Control System

|

–

|

SYNTEC |

|

Floorspace(L*W*H)

|

mm

|

1750*2350*2680

|

|

Machine Weight(Gross)

|

kg

|

2800

|

Reviews

There are no reviews yet.