Description

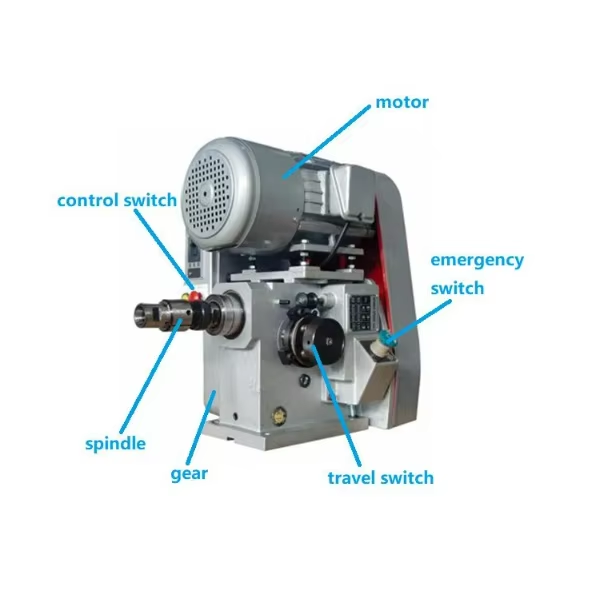

Mini Vertical/Horizontal Equal Pitch Automatic Tapping Machine SCJGTT Series

| Model | SCJGTT4508 | SCJGTT6516 | SCJGTT6532 |

| Max.Swing | 330mm | 430mm | 460mm |

| Tapping capacity | M2-M8(brass/iron) ; below M10(brass/zinc) | M5-M16 | M10-M32 |

| The spindle taper | B16 | MT2 | MT3 |

| Maximum spindle stroke | 45mm | 65mm | 65mm |

| Head pitch | 260mm | 300mm | 450mm |

| Distance between spindle end and mesa | 350mm | 470mm | 600mm |

| Table size | 225* 230mm | 340*340mm | 340*380mm |

| Base size | 415*300mm | 580*425mm | 600*480mm |

| The motor | 3H 4P 0.75kw(1HP) | 3H 4P 1.5kw(2HP) | 3H 6P 2.2kw(3HP) |

| voltage | 380V | 380V | 380V |

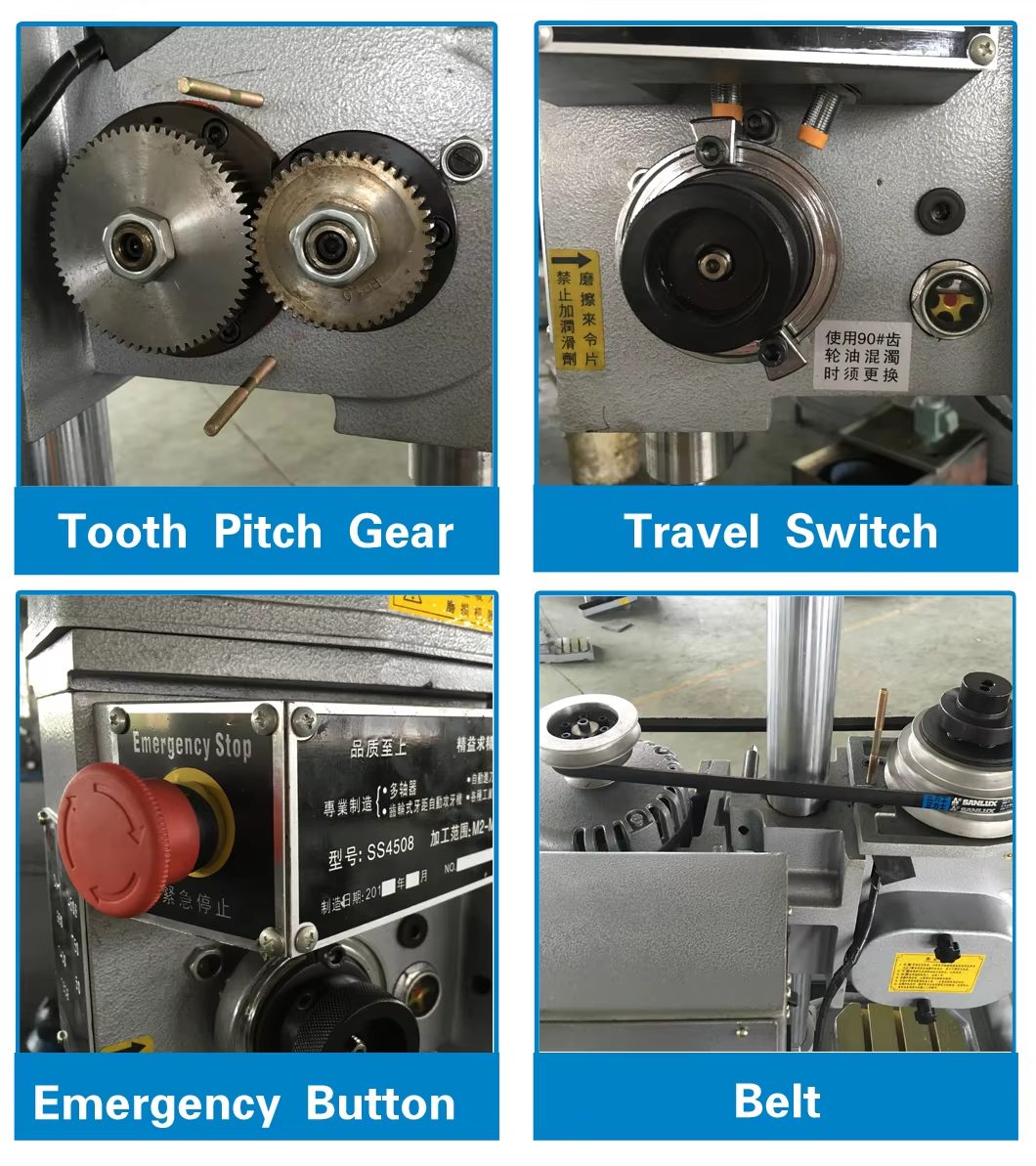

| No. of Spindle Swing | 50HZ 1340/760/420 ; 60HZ 1600/900/500 | 50HZ 505/285/155 ; 60HZ 620/340/190 | 50HZ 200/100/50 ; 60HZ 240/120/60 |

| Auto Feeder Pitch | Imperial: 64/56/48/44/40/32/28/24/20/18/16

Metric:0.2/0.25/0.3/0.35/0.4/0.45/0.5/0.6/ 0.7/0.75/0.8/0.9/1.0/1.25 |

Imperial: 28/24/20/19/18/16/14/12/11/10

Metric:0.7/0.8/0.9/1.0/1.25/1.5/1.75/1.8/2.0/2.5 |

Imperial: 19/16/14/12/11/10/9/8

Metric:1.5/1.75/2.0/2.5/3.0/3.5 |

| Frequency | 50HZ | 50HZ | 50HZ |

| Multi-axis maximum capacity | M3*10axis M4*5axis | M6*8axis M8*4axis M12*2axis | M10*10axis M16*4axis M20*2axis |

| Weight | 150Kg/100Kg | 200kg/150kg | 300kg/250kg |

| volume | 460*630*1060mm | 480*930*1150mm | 920*850*1200mm |

Machine Features:

1. Special forward and reverse motor design, low inertia, to prevent tapping breakage.

2. The motor is equipped with an independent cooling fan for forced heat dissipation, which can operate continuously and is durable.

3. The spindle can operate continuously at high speed, and employees only need to place the processed products, which is easy, convenient, safe, and efficient.

4. Especially suitable for micro hole and blind hole processing of precision hardware such as clocks, glasses, mobile phones, cameras, etc.

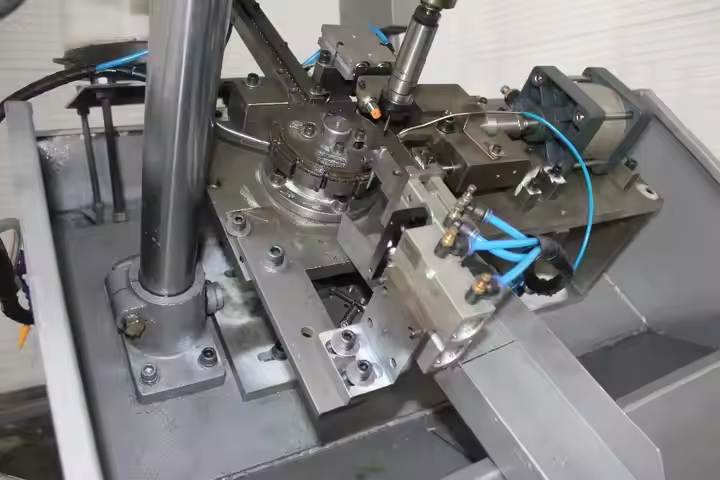

5. It can be equipped with a multi axis tapping device to complete multi hole tapping in one go, while also completing automatic tapping to improve production efficiency.

6. Solid column, tempered to relieve stress, plated with hard chromium, friction resistant, and rust free.

7. Functional action can be selected for perforated teeth,blind teeth and perforated teeth

8. The spindle rotation speed is high and the spindle speed is low when the tapping is reversed, and the accuracy of tapping depth is 0.1mm

Non Standard Goods:

Non standard goods refer to goods or equipment that are not made according to the work standards and specifications published by the country, but are made according to one’s own needs and plans. And if the appearance or function is not included in the national equipment product catalog, products produced, modified or customized based on user requests and standardized products are called non-standard products.

Enquiry Notice for Customerized Machine:

1. The customer provides the required parts for processing, assembly, and riveting, and clarifies a series of information about the parts, such as tolerances, burrs, deformation, etc.

2. We will conduct a series of analyses on the components provided by the customer and provide a quotation

Reviews

There are no reviews yet.