Description

|

Type

|

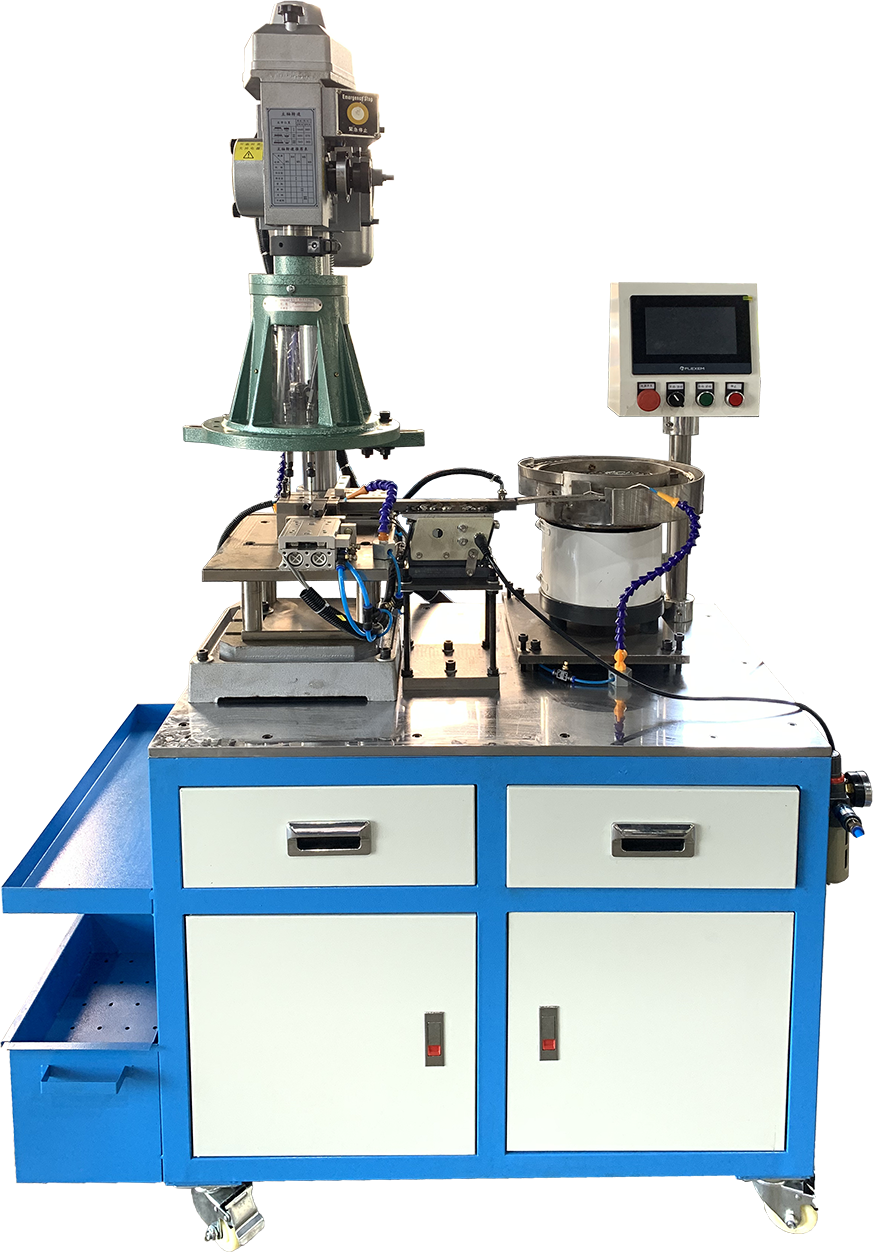

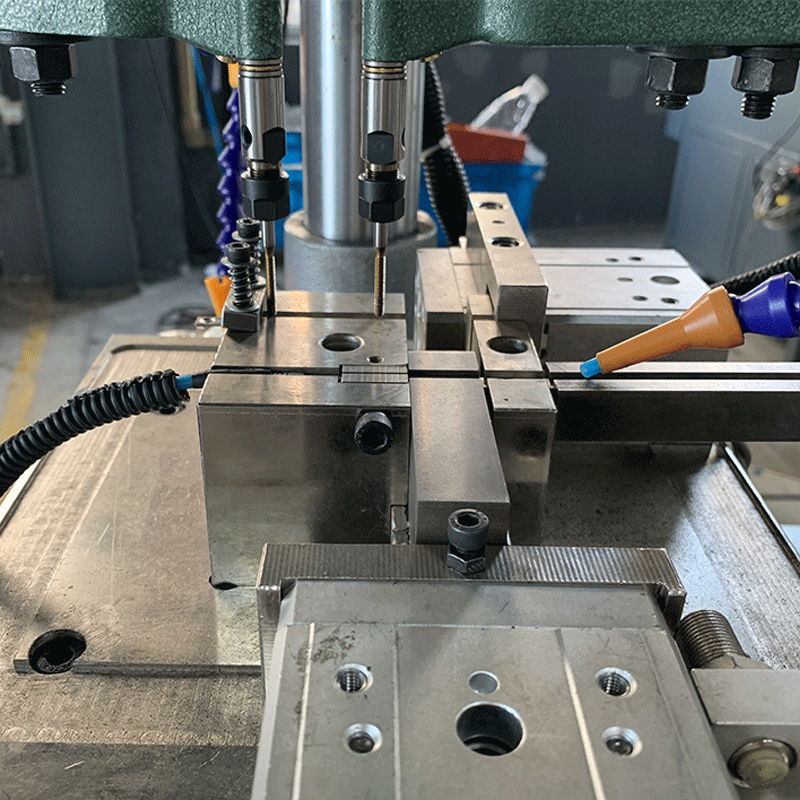

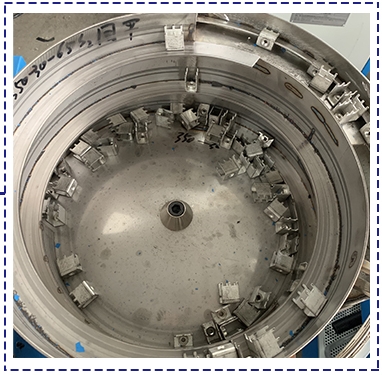

Customzied Drilling and Tapping Machine

|

|

Model Number

|

SCJTD1

|

|

Core Components

|

Bearing, Pump, Gear, motor, Gearbox, PLC, Pressure vessel, Engine

|

|

Max. Drilling Dia. (mm)

|

Based on actual case

|

|

Drilling Speed

|

Based on actual case

|

|

Voltage

|

220V/380V

|

|

Dimension(L*W*H)

|

Based on actual case

|

|

Power (kW)

|

Based on actual case

|

|

Warranty

|

1 Year

|

|

Feature

|

Full Automatic loading and uploading ;Save Manpower; High Efficiency

|

|

Max. drilling diameter

|

Based on actual case

|

|

Precision

|

High Precision

|

|

Machine type

|

CNC Servo Auto

|

|

After-sales Service Provided

|

Online Support Video Technical Support

|

Machine Features:

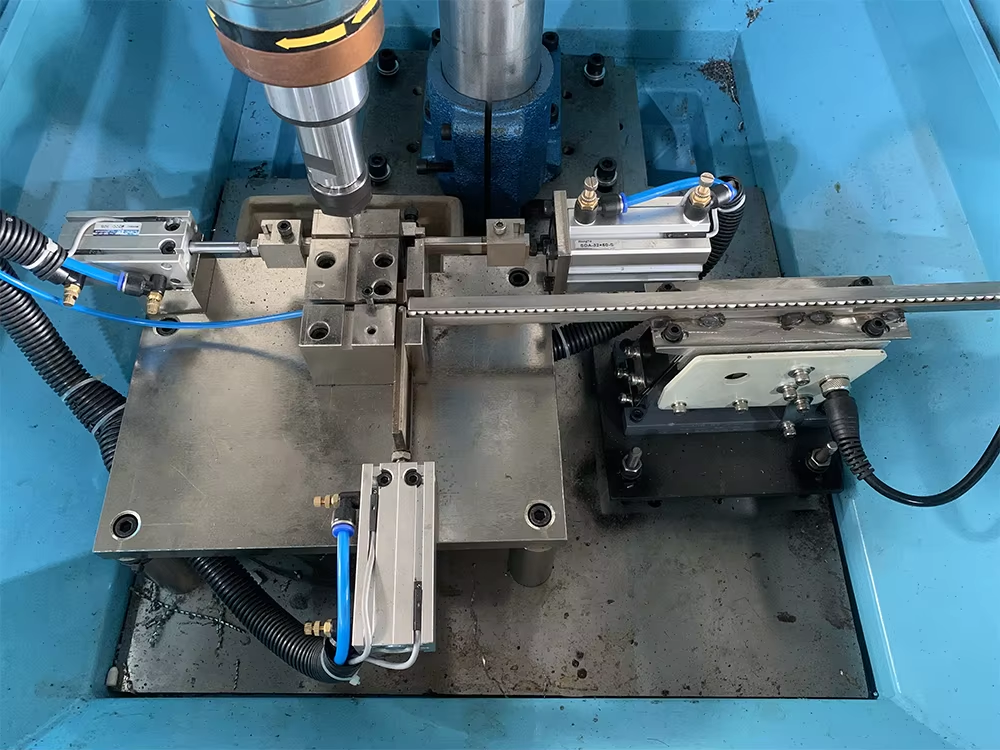

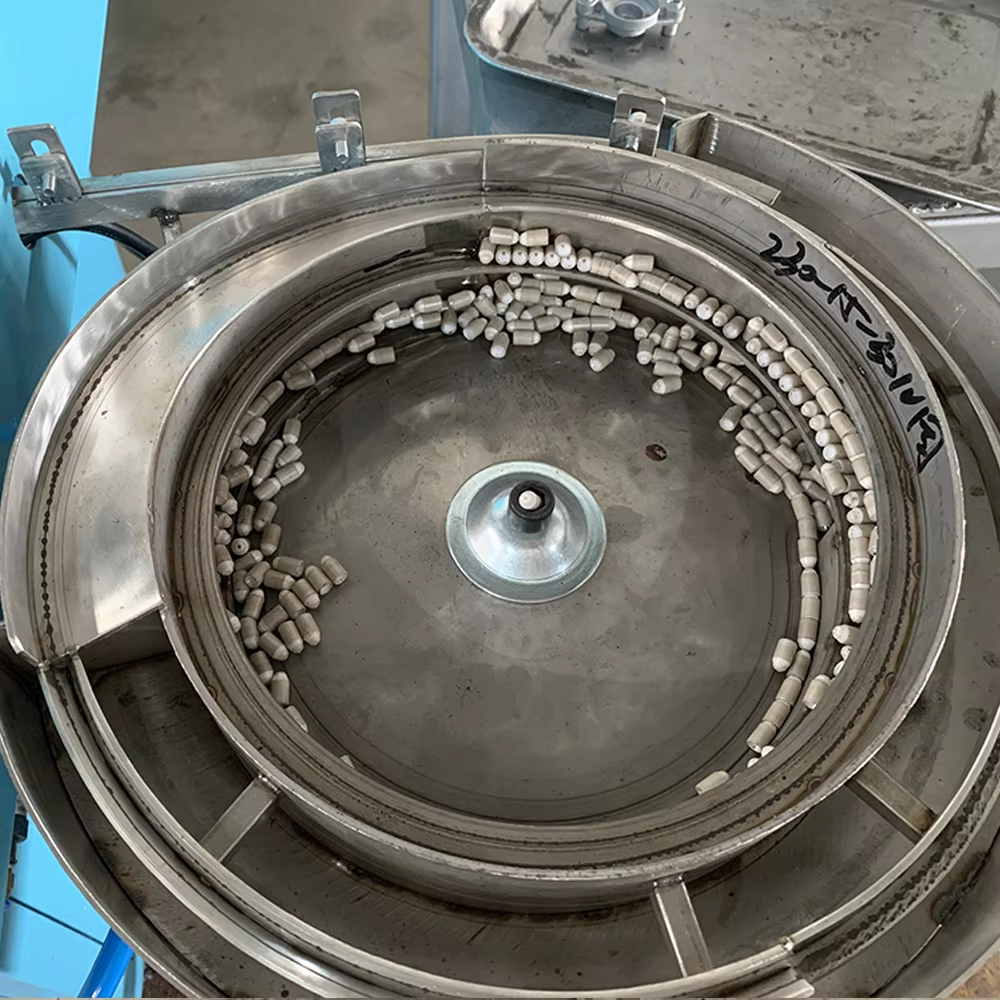

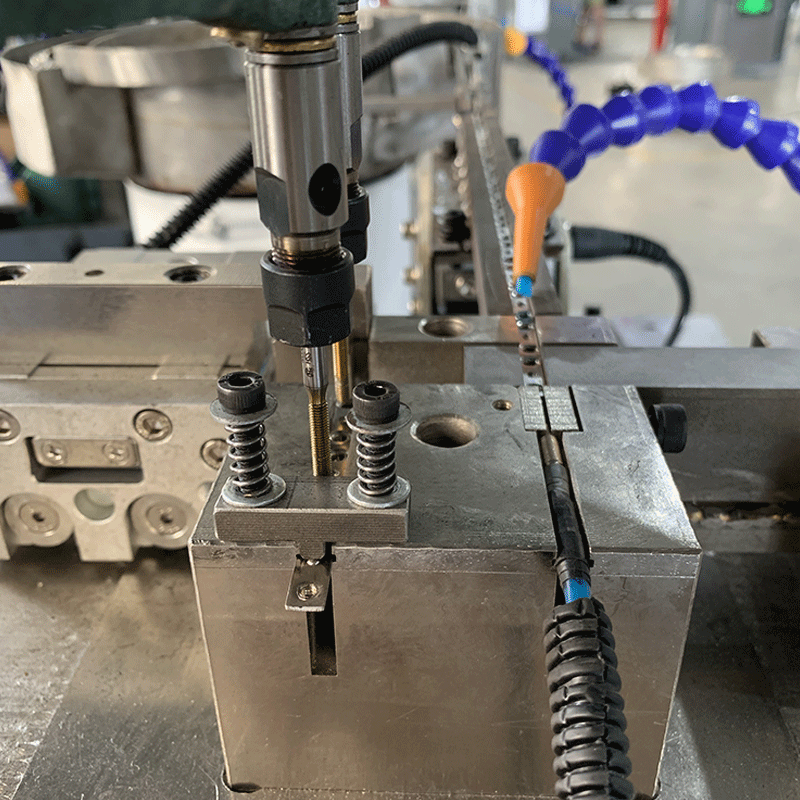

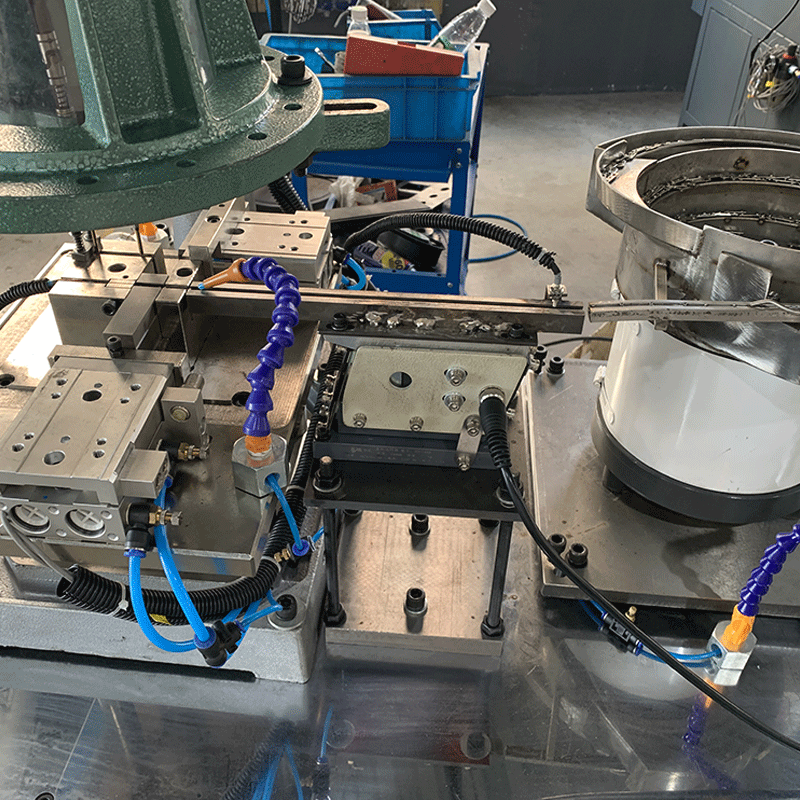

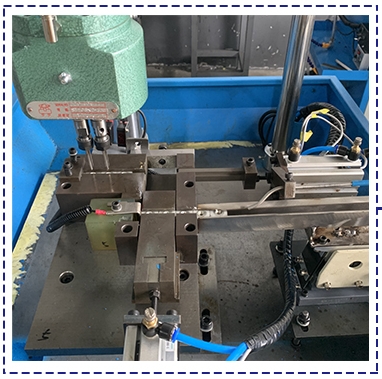

● This machine is a standard machine for standardized production.As long as the workpiece can be directionally put into the track through thefeeding machine,the machine can do full-automatic drilling and fapping operation.

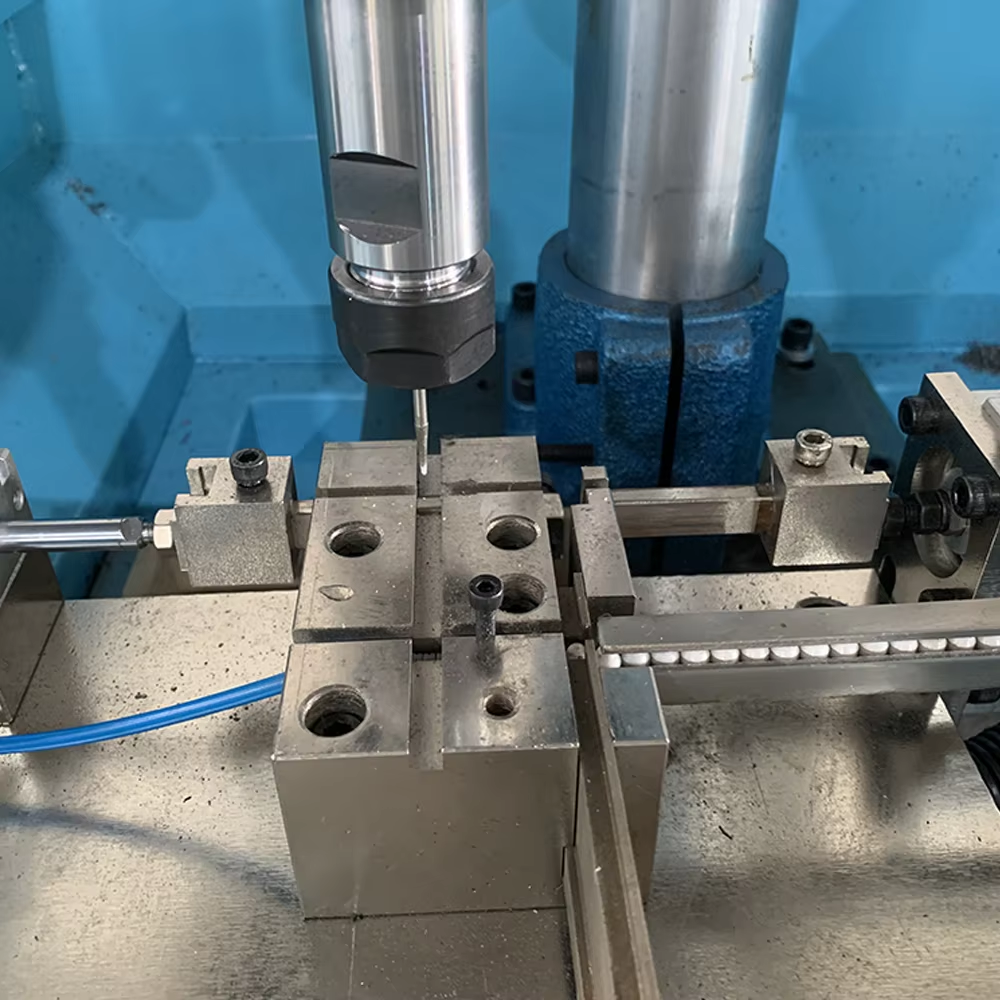

● Drilling and tapping can be applied independently.

● Fully automatic tapping,spacing and depth.of teeth are accurate,and the product consistency is high.

● Applicable to the same specifications of products in mass production occasions,improve efficiency,reduce labor,one person can operate

● Through hole and blind hole can be machined.There are safety devices for feeding,torsion,radial and clamping to ensure the service lifemore than one machine.

● It is easy to change specifications and increase cooling system to ensure the quality of dental grain.

● Drll bit or tapping breakage induction device can be installed to detect if necessary.

Non Standard Goods:

Non standard goods refer to goods or equipment that are not made according to the work standards and specifications published by the country, but are made according to one’s own needs and plans. And if the appearance or function is not included in the national equipment product catalog, products produced, modified or customized based on user requests and standardized products are called non-standard products.

Enquiry Notice for Customerized Machine:

1. The customer provides the required parts for processing, assembly, and riveting, and clarifies a series of information about the parts, such as tolerances, burrs, deformation, etc.

2. We will conduct a series of analyses on the components provided by the customer and provide a quotation

Reviews

There are no reviews yet.